Product Description

Product Description

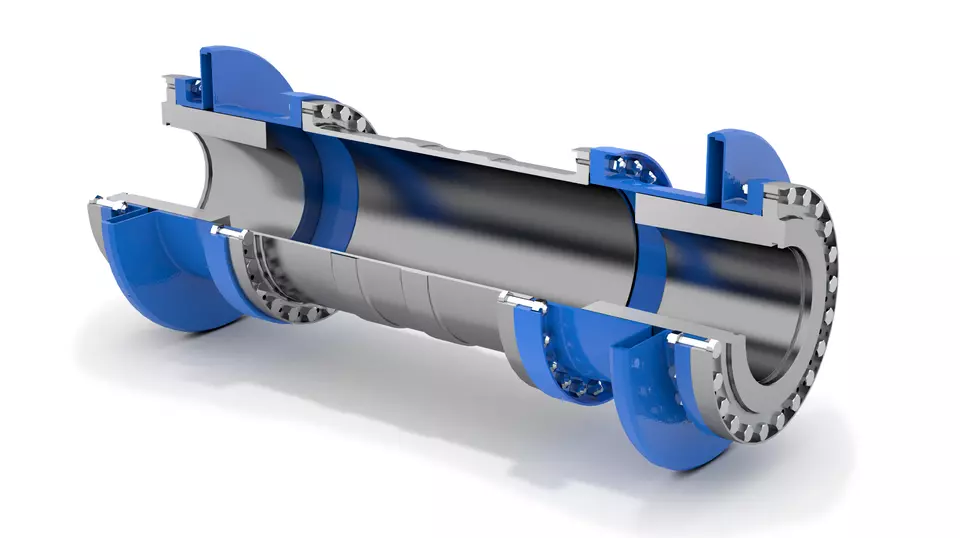

Coupling Deatails

Name: High precision plum blossom

coupling Model: LM-Material: Aviation Aluminum Alloy

Working temperature: -40 ° C ~ 100 ° C

Support customization: Factory direct sales support customization.

Features:

1.Intermediate Elastomer Connection-Absorbs vibration, compensates for radial, angular, and axial 2.misalignment

3.Oil resistance and electrical insulation

4.Clockwise and counterclockwise rotation characteristics are identical-there are 3 different hardness 5.elastomer

6.Fixation by clamping screw.

Product Parameters

|

Model No |

D(mm) |

L(mm) |

d1(min) |

d2(max) |

|

19*26 |

19 |

26 |

3 |

8 |

|

26*35 |

26 |

35 |

4 |

10 |

|

32*41 |

32 |

41 |

6 |

14 |

|

34*45 |

34 |

45 |

6 |

14 |

|

39*49 |

39 |

49 |

8 |

19 |

|

44*50 |

44 |

50 |

8 |

22 |

|

50*55 |

50 |

55 |

8 |

26 |

|

56*63 |

56 |

63 |

10 |

28 |

|

68*74 |

68 |

74 |

12 |

35 |

|

82*98 |

82 |

98 |

14 |

45 |

Detailed Photos

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Diaphragm Couplings Operate in High-Temperature or Corrosive Environments?

Yes, diaphragm couplings can be designed and manufactured to operate in high-temperature or corrosive environments, depending on the materials used in their construction. Here’s how diaphragm couplings can handle these challenging conditions:

High-Temperature Environments:

For applications involving high temperatures, manufacturers can use heat-resistant materials for the diaphragm and other coupling components. Some common high-temperature materials include:

- Stainless Steel Alloys: Certain stainless steel alloys, such as Inconel or Hastelloy, are known for their excellent high-temperature properties. These alloys can withstand elevated temperatures without significant deformation or loss of strength.

- Titanium: Titanium is another material that offers good heat resistance. It is lightweight, strong, and can operate at elevated temperatures, making it suitable for certain high-temperature applications.

- Ceramic Coatings: In some cases, manufacturers apply ceramic coatings to the diaphragm or other components to enhance their heat resistance and protect them from thermal degradation.

By using these high-temperature materials, diaphragm couplings can maintain their performance and integrity in environments with extreme heat, such as steel mills, heat treatment furnaces, and power generation plants.

Corrosive Environments:

Diaphragm couplings can also be designed to withstand corrosive environments by using materials that resist chemical attacks. Some options for corrosive environments include:

- Corrosion-Resistant Stainless Steel: Certain stainless steel alloys, like 316L or Duplex stainless steel, offer excellent resistance to corrosion from chemicals and corrosive agents.

- Specialty Coatings: Manufacturers may apply coatings or platings to the coupling components to provide an additional layer of protection against corrosion.

- Non-Metallic Materials: In some cases, non-metallic materials like PTFE (Teflon) or polypropylene may be used for the diaphragm and other components, as they are highly resistant to chemical corrosion.

By using these corrosion-resistant materials, diaphragm couplings can be used in applications such as chemical processing, wastewater treatment, marine environments, and other situations where exposure to corrosive substances is common.

In summary, diaphragm couplings can be engineered to operate in high-temperature or corrosive environments by selecting appropriate materials that offer the necessary heat resistance and corrosion resistance. When specifying a diaphragm coupling for such applications, it is crucial to consider the specific environmental conditions to ensure the coupling’s long-term performance and reliability.

Real-World Case Studies of Diaphragm Couplings in Engineering Projects

Diaphragm couplings have been successfully utilized in various engineering projects, providing reliable power transmission and addressing specific challenges faced by different industries. Here are some real-world case studies and success stories showcasing the effectiveness of diaphragm couplings:

- Case Study 1: Pumping System in Wastewater Treatment Plant

- Case Study 2: Turbine-Generator Coupling in Power Plant

- Case Study 3: Industrial Compressor System

In a wastewater treatment plant, a critical pumping system was experiencing frequent breakdowns due to misalignment issues and vibration-related failures. The plant engineers decided to replace the existing gear couplings with diaphragm couplings to address these problems. The diaphragm couplings’ flexibility allowed them to compensate for the misalignment caused by thermal expansion and pump impeller wear. Additionally, the couplings’ ability to dampen vibrations reduced stress on the pump bearings, resulting in extended maintenance intervals and increased overall system reliability. The successful implementation of diaphragm couplings in this project led to significant cost savings by minimizing downtime and reducing the need for frequent maintenance.

In a power generation plant, a large gas turbine-generator coupling required replacement due to excessive wear and fatigue-related failures in the previous coupling. The plant engineers opted for a high-performance diaphragm coupling with improved fatigue resistance and higher torque capacity. The flexibility of the diaphragm coupling allowed it to accommodate slight misalignments between the turbine and the generator during operation. This capability reduced the stress on the coupling and mitigated the risk of premature failure. The diaphragm coupling’s ability to handle torsional vibrations and dampen mechanical resonance further improved the overall reliability and performance of the turbine-generator system, resulting in increased power generation efficiency and reduced maintenance costs.

In an industrial compressor application, the existing coupling experienced frequent failures due to misalignment and shock loads from varying compression demands. The plant engineers replaced the old coupling with a diaphragm coupling featuring high misalignment tolerance and excellent shock absorption properties. The diaphragm coupling’s flexibility effectively compensated for the misalignment between the compressor and the motor, resulting in smoother operation and reduced stress on the drive components. Additionally, the coupling’s ability to absorb sudden shock loads reduced the risk of equipment damage and minimized unplanned downtime. The successful implementation of the diaphragm coupling significantly improved the compressor system’s reliability and contributed to increased productivity in the industrial facility.

These case studies demonstrate the successful application of diaphragm couplings in diverse engineering projects, including wastewater treatment plants, power generation facilities, and industrial compressors. The flexibility, misalignment compensation, and vibration dampening properties of diaphragm couplings have proven to be valuable in addressing specific challenges and enhancing the performance and reliability of critical machinery in various industries.

Types of Diaphragm Couplings and Their Specific Applications

Diaphragm couplings come in various designs and materials, each suited for specific applications. Here are some of the different types of diaphragm couplings and their specific applications:

- Metal Diaphragm Couplings:

- Industrial machinery such as pumps, compressors, and generators

- Motion control systems in robotics and automation

- Paper and printing machinery

- Machine tools and CNC equipment

- Marine and offshore equipment

- Aerospace systems

- Elastomeric Diaphragm Couplings:

- Pumps and compressors in HVAC systems

- Power transmission in agricultural machinery

- Automotive drivetrain components

- Small engine applications

- Medical equipment

- High-Temperature Diaphragm Couplings:

- Steel and metal processing industries

- Heat treatment furnaces

- Power generation plants

- Chemical processing equipment

- Glass and ceramic manufacturing

- Non-Metallic Diaphragm Couplings:

- Electrical machinery and equipment

- Semiconductor manufacturing

- Food and beverage processing

- Pharmaceutical and biotechnology applications

Metal diaphragm couplings are the most common type and are often made of stainless steel or other high-strength alloys. They are used in a wide range of applications that require high torque transmission, precision, and reliability. Some common applications include:

Elastomeric diaphragm couplings have a flexible diaphragm made of elastomeric materials like rubber or urethane. They offer vibration dampening properties and are suitable for applications that require shock absorption and noise reduction. Specific applications include:

These couplings are designed to withstand high temperatures, making them suitable for applications in extreme heat environments. They are commonly used in:

Non-metallic diaphragm couplings are made from materials like polyurethane or other composites. They are often used in applications where electrical isolation or non-magnetic properties are required. Specific applications include:

Each type of diaphragm coupling offers unique features and advantages, making them suitable for various industries and applications. When selecting a diaphragm coupling, it’s essential to consider factors like torque requirements, misalignment tolerance, environmental conditions, and specific performance characteristics to ensure the coupling’s optimal performance in the intended application.

editor by CX 2024-04-29