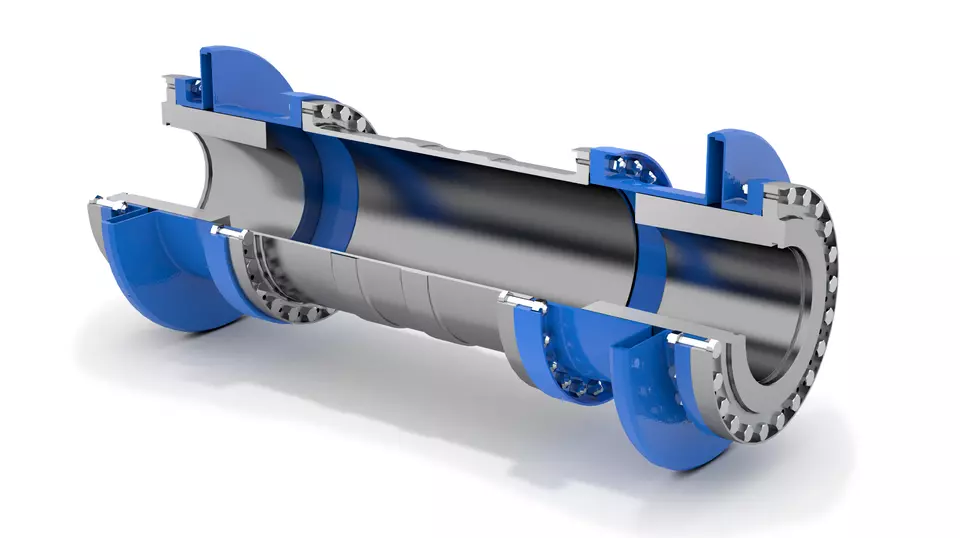

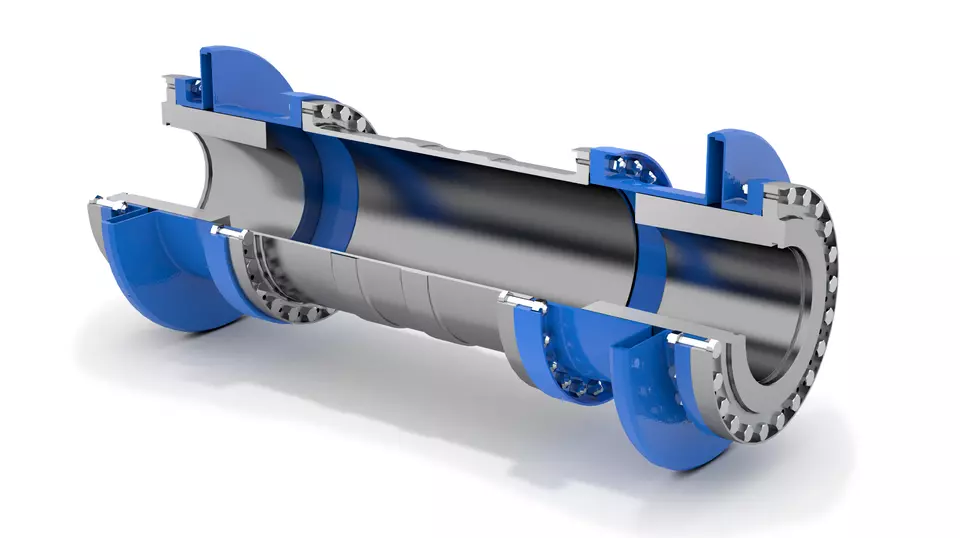

Product Description

GS-39×34.5 Aluminum alloy single diaphragm clamping coupling

Description of GS-39×34.5 Aluminum alloy single diaphragm clamping coupling

>High torque rigidity, can accurately control the rotation of the shaft, can carry out high-precision control

>Designed for servo and stepping motor

>No gap between the shaft and sleeve connection, general for positive and negative rotation

>Low inertia, suitable for high speed operation

>The diaphragm is made of spring steel with excellent fatigue resistance

>Fastening method of clamping screw

Catalogue of GS single diaphragm clamping coupling

| model parameter | common bore diameter d1,d2 | ΦD | L | LF | S | F | M | tightening screw torque |

| (N.M) | ||||||||

| GS-19X20 | 3,4,5,6,6.35,7,8 | 19 | 20 | 9.1 | 1.8 | 3.3 | M2.5 | 1 |

| GS-26X26 | 3,4,5,6,6.35,7,8,9,9.525,10,11,12,14 | 26 | 26 | 11.65 | 2.6 | 3.9 | M3 | 1.5 |

| GS-32X28 | 5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15, | 32 | 28 | 12.25 | 3.5 | 3.85 | M3 | 1.5 |

| GS-34X32 | 5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15,16 | 34 | 32 | 14.25 | 3.5 | 4.85 | M4 | 2.5 |

| GS-39X34.5 | 8,9,9.525,10,11,12,12.7,14,15,16,17,18,19 | 39 | 34.5 | 14.9 | 4.5 | 5 | M4 | 2.5 |

| GS-44X34.5 | 8,9,9.525,10,11,12,12.7,14,15,16,17,18,19,20,22,24 | 44 | 34.5 | 14.9 | 4.5 | 5 | M4 | 2.5 |

| GS-50X46 | 8,9,9525,10,11,12,12.7,14,15,16,17,18,19,20,22,24,25 | 50 | 46 | 20.6 | 4.8 | 6 | M5 | 7 |

| GS-56X45 | 10,12,14,15,16,17,18,19,20,22,24,25,28,30,32 | 56 | 45 | 19.75 | 5.5 | 6.4 | M5 | 7 |

| GS-68X53 | 12,14,15,16,17,18,19,20,22,24,25,28,30,32,35,38 | 68 | 53 | 23.35 | 6.3 | 7.7 | M6 | 12 |

| model parameter | Rated torque | allowable eccentricity | allowable deflection angle | allowable axial deviation | maximum speed | static torsional stiffness | moment of inertia | Material of shaft sleeve | Material of shrapnel | surface treatment | weight |

| (N.M)* | (mm)* | (°)* | (mm)* | rpm | (N.M/rad) | (Kg.M2) | (g) | ||||

| GS-19X20 | 1 | 0.1 | 1 | ±0.09 | 1000 | 220 | 6.7×10-6 | High strength aluminum alloy | S U S 3 0 4 Spring steel | Anodizing treatment | 11 |

| GS-26X26 | 1.5 | 0.1 | 1 | ±0.14 | 11000 | 1125 | 2.2×10-6 | 28 | |||

| GS-32×28 | 2 | 0.1 | 1 | ±0.18 | 11000 | 21000 | 7.1×10-6 | 46 | |||

| GS-34X32 | 3 | 0.1 | 1 | ±0.18 | 11000 | 2250 | 8.0×10-6 | 55 | |||

| GS-39X34.5 | 6 | 0.1 | 1 | ±0.23 | 11000 | 3900 | 2.2×10-5 | 81 | |||

| GS-44X34.5 | 9 | 0.1 | 1 | ±0.27 | 11000 | 4500 | 2.8×10-5 | 99 | |||

| GS-55X46 | 18 | 0.1 | 1 | ±0.30 | 11000 | 6500 | 2.5×10-5 | 135 | |||

| GS-56X45 | 25 | 0.1 | 1 | ±0.36 | 11000 | 12900 | 1.2×10-4 | 217 | |||

| GS-68X53 | 60 | 0.1 | 1 | ±0.4 | 9000 | 25800 | 1.5×10-4 | 348 | |||

| GS-82X68 | 100 | 0.1 | 1 | ±0.5 | 8000 | 38700 | 1.8×10-5 | 689 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Diaphragm Couplings Operate in High-Temperature or Corrosive Environments?

Yes, diaphragm couplings can be designed and manufactured to operate in high-temperature or corrosive environments, depending on the materials used in their construction. Here’s how diaphragm couplings can handle these challenging conditions:

High-Temperature Environments:

For applications involving high temperatures, manufacturers can use heat-resistant materials for the diaphragm and other coupling components. Some common high-temperature materials include:

- Stainless Steel Alloys: Certain stainless steel alloys, such as Inconel or Hastelloy, are known for their excellent high-temperature properties. These alloys can withstand elevated temperatures without significant deformation or loss of strength.

- Titanium: Titanium is another material that offers good heat resistance. It is lightweight, strong, and can operate at elevated temperatures, making it suitable for certain high-temperature applications.

- Ceramic Coatings: In some cases, manufacturers apply ceramic coatings to the diaphragm or other components to enhance their heat resistance and protect them from thermal degradation.

By using these high-temperature materials, diaphragm couplings can maintain their performance and integrity in environments with extreme heat, such as steel mills, heat treatment furnaces, and power generation plants.

Corrosive Environments:

Diaphragm couplings can also be designed to withstand corrosive environments by using materials that resist chemical attacks. Some options for corrosive environments include:

- Corrosion-Resistant Stainless Steel: Certain stainless steel alloys, like 316L or Duplex stainless steel, offer excellent resistance to corrosion from chemicals and corrosive agents.

- Specialty Coatings: Manufacturers may apply coatings or platings to the coupling components to provide an additional layer of protection against corrosion.

- Non-Metallic Materials: In some cases, non-metallic materials like PTFE (Teflon) or polypropylene may be used for the diaphragm and other components, as they are highly resistant to chemical corrosion.

By using these corrosion-resistant materials, diaphragm couplings can be used in applications such as chemical processing, wastewater treatment, marine environments, and other situations where exposure to corrosive substances is common.

In summary, diaphragm couplings can be engineered to operate in high-temperature or corrosive environments by selecting appropriate materials that offer the necessary heat resistance and corrosion resistance. When specifying a diaphragm coupling for such applications, it is crucial to consider the specific environmental conditions to ensure the coupling’s long-term performance and reliability.

How Does the Flexibility of Diaphragm Couplings Enhance Their Performance in Challenging Environments?

Diaphragm couplings’ flexibility is a key feature that enhances their performance in challenging environments. The ability to flex and compensate for misalignments provides several advantages, making them well-suited for various industrial applications. Here’s how the flexibility of diaphragm couplings contributes to their enhanced performance:

- Misalignment Compensation:

- Vibration Dampening:

- Shock Absorption:

- Temperature Variations:

One of the primary benefits of diaphragm couplings’ flexibility is their ability to accommodate misalignments between the connected shafts. In real-world applications, it is challenging to achieve perfect alignment between shafts due to factors like thermal expansion, shaft deflection, and machine assembly tolerances. Diaphragm couplings can handle axial, angular, and parallel misalignments, ensuring smooth operation even in situations where misalignments may occur during machine operation. By compensating for misalignment, diaphragm couplings reduce stress on the shafts and connected machinery, minimizing the risk of premature wear and failure.

The flexibility of diaphragm couplings allows them to absorb and dampen vibrations that can arise during machine operation. Vibrations can be caused by factors like imbalances, load fluctuations, and mechanical resonances. Diaphragm couplings act as a vibration buffer, attenuating vibration transmission from one shaft to another. This dampening effect helps reduce the risk of mechanical resonance, which can lead to increased stresses and premature failure of components. By dampening vibrations, diaphragm couplings contribute to smoother and quieter operation, promoting overall system reliability and longevity.

In some industrial applications, sudden shocks and impacts can occur due to machine start-ups, load changes, or external forces. The flexibility of diaphragm couplings allows them to absorb and distribute the energy generated by these shocks. By absorbing shock loads, diaphragm couplings protect the connected machinery from damage and prevent potential disruptions in the production process. This shock absorption capability is particularly valuable in applications where equipment encounters frequent and varying shock loads.

Diaphragm couplings can operate effectively across a wide range of temperatures. The flexibility of the diaphragm allows it to maintain its performance even in high-temperature environments. This versatility makes diaphragm couplings suitable for applications in industries like steel manufacturing, glass production, and petrochemical processing, where high temperatures are common.

Overall, the flexibility of diaphragm couplings is a significant advantage in challenging environments. By compensating for misalignments, dampening vibrations, absorbing shocks, and withstanding temperature variations, diaphragm couplings ensure reliable and efficient power transmission in various industrial settings. Their ability to enhance system performance and protect machinery from adverse conditions makes them a preferred choice in critical applications that demand durability, precision, and resilience.

Advantages of Diaphragm Coupling Compared to Other Types of Couplings

A diaphragm coupling offers several advantages over other types of couplings, making it a popular choice for various applications. Here are some of the key advantages:

- Torsional Flexibility: Diaphragm couplings provide excellent torsional flexibility, allowing them to compensate for angular, parallel, and axial misalignment between shafts. This flexibility helps in reducing stress on connected equipment and extends their lifespan.

- No Backlash: Unlike some other couplings, diaphragm couplings have no backlash, which means there is no play or free movement between the connected shafts. This characteristic makes them suitable for applications that require precise and accurate motion transmission.

- No Lubrication: Diaphragm couplings are typically maintenance-free since they do not require any lubrication. This reduces the overall maintenance costs and simplifies the operation of the mechanical system.

- High Torque Capacity: Despite their flexible design, diaphragm couplings can handle high torque loads efficiently. This makes them suitable for heavy-duty applications where high power transmission is required.

- Vibration Damping: The flexibility of the diaphragm in the coupling helps in absorbing and dampening vibrations, reducing the risk of damage to connected machinery and improving the overall system’s performance.

- Compact Size: Diaphragm couplings are generally compact and lightweight compared to some other coupling types. This feature makes them suitable for applications with limited space or weight constraints.

- Corrosion Resistance: Diaphragm couplings made from appropriate materials offer excellent corrosion resistance, making them suitable for use in harsh environments or industries where corrosion is a concern.

- Fail-Safe Design: Diaphragm couplings have a fail-safe design, meaning that in the event of diaphragm failure, they do not lead to catastrophic coupling failure. This enhances the safety and reliability of the mechanical system.

- Cost-Effectiveness: Considering their low maintenance requirements, long service life, and efficient torque transmission, diaphragm couplings offer a cost-effective solution for various applications.

In conclusion, diaphragm couplings provide significant advantages over other types of couplings, including torsional flexibility, zero backlash, no lubrication needs, high torque capacity, vibration damping, compact size, corrosion resistance, fail-safe design, and cost-effectiveness. These features make them a preferred choice in a wide range of mechanical systems and industrial applications.

editor by CX 2024-03-28