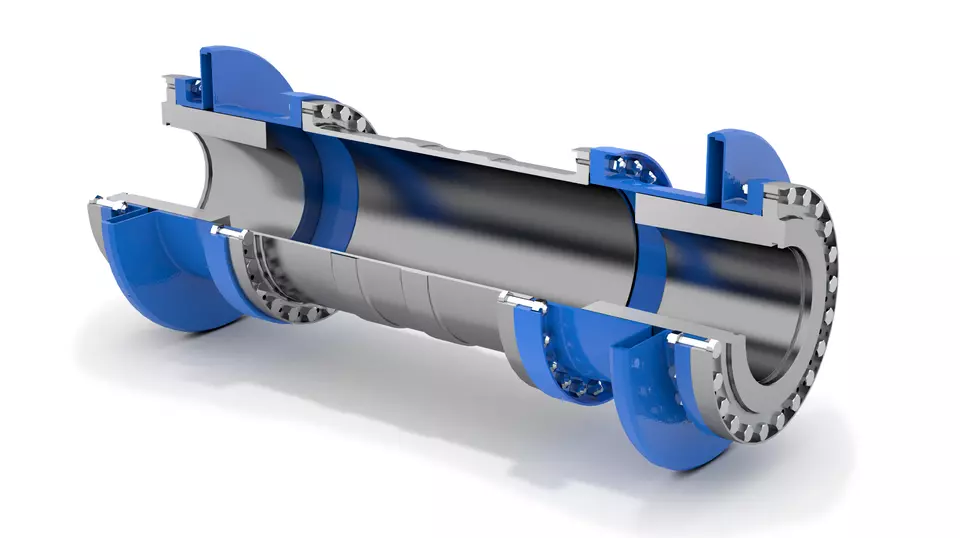

Product Description

Quick Details

| Applicable Industries:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining, Other |

Customized support:

OEM, ODM |

| Product name:Diaphragm Coupling | Surface treatment: Anodizing |

| Place of Origin:ZheJiang , China | Brand Name:REACHJY |

| Application:transmission | Material: steel |

| Certification:ISO9001 | |

Proper Installation of a Diaphragm Coupling for Optimal Performance and Reliability

Proper installation of a diaphragm coupling is essential to ensure its optimal performance and reliability. Here are the steps to follow for a successful installation:

- Inspect the Coupling:

- Shaft Preparation:

- Hub Alignment:

- Tighten Fasteners Correctly:

- Check Runout and Balance:

- Lubrication (if applicable):

- Regular Maintenance:

Before installation, thoroughly inspect the diaphragm coupling for any damage, wear, or deformation. Check for proper alignment of the hubs and make sure they are clean and free from any debris or contaminants.

Ensure that the shafts to be connected are clean, smooth, and free of any burrs or rough edges that could damage the coupling or affect its performance. If necessary, use appropriate tools to deburr and polish the shaft ends.

Align the two hubs of the diaphragm coupling carefully with the shafts. Misalignment during installation can cause premature wear and failure of the coupling. Use alignment tools like dial indicators or laser alignment systems to achieve accurate shaft alignment.

Use the specified torque values and tightening sequence provided by the coupling manufacturer to tighten the fasteners securely. Over-tightening can lead to stress concentrations, while under-tightening can result in loose connections and coupling slippage.

After installation, check the runout of the coupling assembly to ensure that it rotates without wobbling or eccentricity. Also, verify that the coupling is properly balanced to prevent excessive vibrations during operation.

Some diaphragm couplings require lubrication for smooth operation. If lubrication is necessary, follow the manufacturer’s guidelines and use the recommended lubricant to prevent premature wear and reduce friction.

To ensure continued optimal performance, schedule regular inspections and maintenance for the diaphragm coupling. Check for signs of wear, misalignment, or damage, and replace the coupling if necessary. Regular maintenance can help identify potential issues early and prevent unexpected failures.

Following these installation and maintenance guidelines will help maximize the life and performance of the diaphragm coupling, ensuring reliable and efficient operation in various mechanical systems and applications.

How Diaphragm Couplings Handle Torsional Stiffness and Dynamic Balancing in Rotating Machinery

Diaphragm couplings are engineered to address two critical aspects of rotating machinery: torsional stiffness and dynamic balancing. These features ensure efficient power transmission and smooth operation in various industrial applications. Here’s how diaphragm couplings achieve torsional stiffness and dynamic balancing:

- Torsional Stiffness:

- Dynamic Balancing:

Torsional stiffness refers to the ability of a coupling to resist angular deflection or twisting when torque is applied. Diaphragm couplings are designed with a flexible diaphragm made of a high-strength metallic material. This diaphragm connects the two shafts and transmits torque between them.

The design of the diaphragm allows it to flex slightly under load while maintaining its integrity. This controlled flexibility ensures that the diaphragm coupling can handle misalignments and accommodate minor variations in the alignment of the shafts. Despite this flexibility, diaphragm couplings offer high torsional stiffness, ensuring efficient power transmission without significant energy losses due to deformation.

The combination of flexibility and torsional stiffness allows diaphragm couplings to absorb shocks and vibrations, which can occur during start-up or during sudden changes in load. As a result, diaphragm couplings help protect the connected machinery from damage caused by torque fluctuations and torsional vibrations.

Dynamic balancing is crucial to prevent excessive vibrations in rotating machinery, which can lead to premature wear, increased stress on components, and reduced equipment lifespan. Imbalanced rotating parts can cause oscillations and resonance, adversely affecting the overall performance of the system.

Diaphragm couplings are inherently well-balanced due to their symmetrical design and the equal distribution of mass around the center of rotation. This balanced configuration minimizes the generation of vibrations during operation. Additionally, the flexibility of the diaphragm helps dampen any residual vibrations that may arise, further contributing to the dynamic balancing of the system.

In cases where extremely high precision is required, diaphragm couplings can undergo additional balancing processes during manufacturing to fine-tune their dynamic characteristics. This process ensures that the coupling operates optimally even at high rotational speeds.

By efficiently handling torsional stiffness and dynamic balancing, diaphragm couplings contribute to the smooth and reliable operation of rotating machinery across various industries. Their ability to handle misalignments, dampen vibrations, and transmit torque accurately makes them an essential component in many critical applications, such as pumps, compressors, turbines, and more.

Are There Any Industry Standards or Certifications for Diaphragm Couplings?

Yes, there are industry standards and certifications that apply to diaphragm couplings, ensuring their quality, performance, and safety. Some of the notable standards and certifications include:

- American Petroleum Institute (API) Standards: API provides standards for various equipment and components used in the oil and gas industry. For diaphragm couplings used in oil and gas applications, compliance with API standards ensures that the couplings meet specific requirements and are suitable for use in demanding environments.

- American Gear Manufacturers Association (AGMA) Standards: AGMA sets standards for various types of couplings, including diaphragm couplings. These standards cover design considerations, materials, performance, and safety factors, ensuring that couplings adhere to industry best practices.

- International Organization for Standardization (ISO) Standards: ISO has several standards relevant to couplings in general, which can also apply to diaphragm couplings. ISO standards ensure global consistency in terms of design, manufacturing, and performance criteria.

- European Conformity (CE) Marking: Diaphragm couplings intended for sale within the European Economic Area (EEA) must bear the CE marking, indicating that they comply with relevant European Union (EU) directives, including safety and environmental requirements.

- American National Standards Institute (ANSI) Standards: ANSI sets standards for various industrial equipment, including couplings. ANSI standards provide guidelines for design, materials, and performance, ensuring safe and reliable operation.

- Occupational Safety and Health Administration (OSHA) Compliance: Although not a specific certification for diaphragm couplings, compliance with OSHA regulations is essential to ensure the safety of workers who operate and maintain equipment with diaphragm couplings.

Manufacturers of diaphragm couplings often seek these certifications and comply with relevant industry standards to demonstrate the quality and reliability of their products. Customers and end-users can look for these certifications and standards compliance when selecting diaphragm couplings for their applications, as it provides assurance of the coupling’s performance and adherence to safety requirements.

editor by CX 2023-12-07