Product Description

Product Description

The maximum opening value is a circular hole or a tapered hole with a keyway.

Main applications:

DWZ disc eddy current brake is mainly used as load in loading dynamometer equipment. it is experimental apparatus which can measure the dynamic mechanical properties, especially in dynamic loading test whose power value is small or tiny, also can be treated as suction power devices of other dynamic devices.

DW series disc eddy current dynamometer is, is that add device for measuring torque and rotational speed on DWZ series disc eddy current brake, it is experimental apparatus which can measure the dynamic mechnical properties, especial in dynamic loading test whose power value is small or tiny.

CW eddy current brake as a load is mainly used to measure the mechanical characteristics of inspection equipment, it and other control instrument (including loading apparatus, torque speed sensor and torque power acquisition instrument etc.) can be composed of eddy current dynamometer can be used for performance testing of the internal combustion engine, motor, gas turbine, automobile and its dynamic mechanical components, compared with other power measuring device, the CW series power measuring device has the advantages of reliability, high stability and practicability.

| Eddy current brake/dynamometer | Rated Power | Rated torque | Rated speed | Maximum rotational speed | Turning inertia | Maximum excitation voltage | Maximum excitation Current | Cooling water pressure | Flow of the cooling water |

| DWZ/DW-0.75 | 0.75 | 5 | 2000-2600 | 16000 | 0.002 | 80 | 3 | 0.1~0.3 | 1 |

| DWZ/DW-3 | 3 | 10 | 2000-2600 | 14000 | 0.003 | 80 | 3 | 0.1~0.3 | 2 |

| DWZ/DW-6 | 6 | 25 | 2000-2600 | 14000 | 0.003 | 80 | 3 | 0.1~0.3 | 3 |

| DWZ/DW-10 | 10 | 50 | 2000-2600 | 13000 | 0.01 | 80 | 3 | 0.1~0.3 | 4.5 |

| DWZ/DW-16 | 16 | 70 | 2000-2600 | 13000 | 0.02 | 80 | 3.5 | 0.1~0.3 | 6.5 |

| DWZ/DW-25 | 25 | 120 | 2000-2600 | 11000 | 0.05 | 80 | 3.5 | 0.1~0.3 | 15 |

| DWZ/DW-40 | 40 | 160 | 2000-2600 | 10000 | 0.1 | 90 | 4 | 0.1~0.3 | 25 |

| DWZ/DW-63 | 63 | 250 | 2000-2600 | 9000 | 0.18 | 90 | 4 | 0.1~0.3 | 45 |

| DWZ/DW-100 | 100 | 400 | 2000-2600 | 8500 | 0.32 | 120 | 4 | 0.1~0.3 | 60 |

| DWZ/DW-160 | 160 | 600 | 2000-2600 | 8000 | 0.52 | 120 | 5 | 0.1~0.3 | 100 |

| DWZ/DW-250 | 250 | 1100 | 2000-2600 | 7000 | 1.8 | 150 | 5 | 0.2~0.4 | 180 |

| DWZ/DW-300 | 300 | 1600 | 2000-2600 | 6000 | 2.7 | 150 | 5 | 0.2~0.4 | 210 |

| DWZ/DW-400 | 400 | 2200 | 2000-2600 | 5000 | 3.6 | 180 | 10 | 0.2~0.4 | 300 |

| DWZ/DW-630 | 630 | 3600 | 2000-2600 | 5000 | 5.3 | 180 | 10 | 0.2~0.4 | 450 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

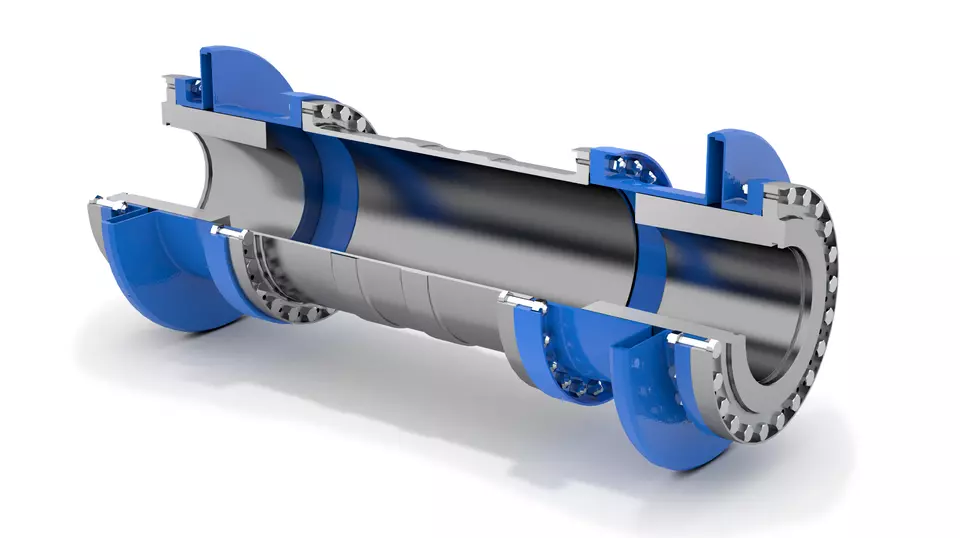

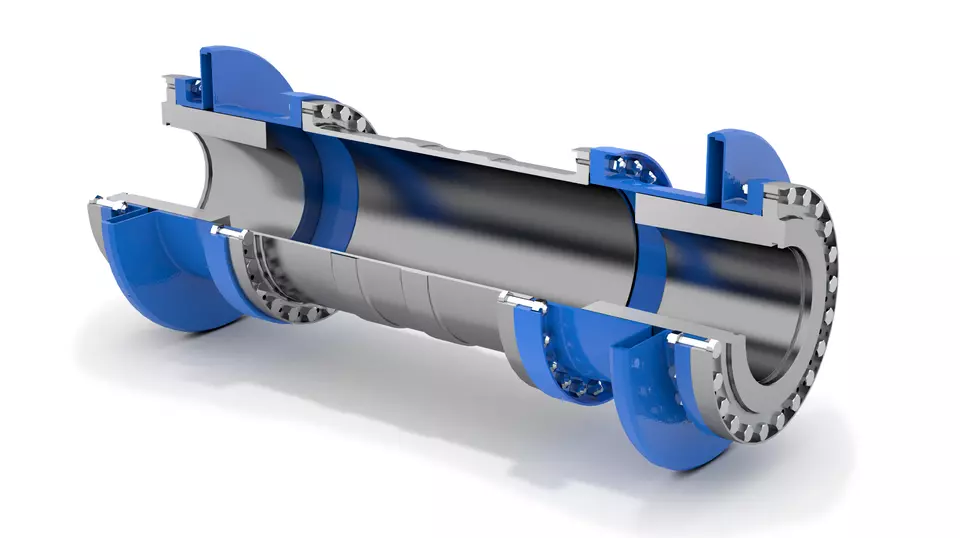

Can Diaphragm Couplings Operate in High-Temperature or Corrosive Environments?

Yes, diaphragm couplings can be designed and manufactured to operate in high-temperature or corrosive environments, depending on the materials used in their construction. Here’s how diaphragm couplings can handle these challenging conditions:

High-Temperature Environments:

For applications involving high temperatures, manufacturers can use heat-resistant materials for the diaphragm and other coupling components. Some common high-temperature materials include:

- Stainless Steel Alloys: Certain stainless steel alloys, such as Inconel or Hastelloy, are known for their excellent high-temperature properties. These alloys can withstand elevated temperatures without significant deformation or loss of strength.

- Titanium: Titanium is another material that offers good heat resistance. It is lightweight, strong, and can operate at elevated temperatures, making it suitable for certain high-temperature applications.

- Ceramic Coatings: In some cases, manufacturers apply ceramic coatings to the diaphragm or other components to enhance their heat resistance and protect them from thermal degradation.

By using these high-temperature materials, diaphragm couplings can maintain their performance and integrity in environments with extreme heat, such as steel mills, heat treatment furnaces, and power generation plants.

Corrosive Environments:

Diaphragm couplings can also be designed to withstand corrosive environments by using materials that resist chemical attacks. Some options for corrosive environments include:

- Corrosion-Resistant Stainless Steel: Certain stainless steel alloys, like 316L or Duplex stainless steel, offer excellent resistance to corrosion from chemicals and corrosive agents.

- Specialty Coatings: Manufacturers may apply coatings or platings to the coupling components to provide an additional layer of protection against corrosion.

- Non-Metallic Materials: In some cases, non-metallic materials like PTFE (Teflon) or polypropylene may be used for the diaphragm and other components, as they are highly resistant to chemical corrosion.

By using these corrosion-resistant materials, diaphragm couplings can be used in applications such as chemical processing, wastewater treatment, marine environments, and other situations where exposure to corrosive substances is common.

In summary, diaphragm couplings can be engineered to operate in high-temperature or corrosive environments by selecting appropriate materials that offer the necessary heat resistance and corrosion resistance. When specifying a diaphragm coupling for such applications, it is crucial to consider the specific environmental conditions to ensure the coupling’s long-term performance and reliability.

Design Considerations for Selecting a Diaphragm Coupling for a Specific Application

When choosing a diaphragm coupling for a particular application, several crucial design considerations should be taken into account. Each application has unique requirements, and selecting the right diaphragm coupling can significantly impact the overall performance and reliability of the system. Here are the key design considerations:

- 1. Torque Capacity:

- 2. Misalignment Tolerance:

- 3. Speed and RPM:

- 4. Operating Environment:

- 5. Space Constraints:

- 6. Maintenance Requirements:

- 7. Application-specific Factors:

Determine the maximum torque that the diaphragm coupling will need to transmit in the application. Select a diaphragm coupling with a torque capacity that comfortably exceeds the application’s peak torque requirements. Consider potential torque variations during operation and choose a coupling that can handle the dynamic torque conditions, especially in machines with frequent start-stop cycles or load fluctuations.

Assess the potential misalignment between the connected shafts in the application. Diaphragm couplings are known for their ability to compensate for various types of misalignment, such as axial, angular, and parallel misalignment. Determine the expected misalignment angles and choose a diaphragm coupling with the appropriate misalignment capabilities to ensure smooth operation and minimize stress on the coupling and connected machinery.

Consider the rotational speed and RPM (revolutions per minute) requirements of the application. Diaphragm couplings are suitable for high-speed applications due to their balanced design and ability to dampen vibrations. Ensure that the selected coupling can handle the required RPM without encountering critical speed issues or exceeding its rated limitations.

Evaluate the environmental conditions in which the diaphragm coupling will operate. Consider factors such as temperature, humidity, presence of corrosive substances, and exposure to contaminants. Choose a diaphragm coupling made from materials suitable for the specific operating environment to prevent corrosion and premature wear.

Diaphragm couplings have a compact design, making them suitable for applications with limited space. Consider the available installation space and choose a coupling that fits within the available dimensions while providing the required torque capacity and misalignment compensation.

Assess the maintenance requirements of the diaphragm coupling. Some couplings may require periodic lubrication, while others are maintenance-free. Choose a coupling with maintenance requirements that align with the resources and capabilities of the maintenance team.

Consider any unique factors relevant to the application, such as the presence of shock loads, dynamic balancing requirements, or the need for precision in high-accuracy systems. These specific factors can influence the selection of the most suitable diaphragm coupling for the application.

By carefully considering these design factors, engineers and designers can select the most appropriate diaphragm coupling for a specific application. The right coupling choice will enhance the overall performance, reliability, and service life of the machinery or equipment in which it is employed.

Advantages of Diaphragm Coupling Compared to Other Types of Couplings

A diaphragm coupling offers several advantages over other types of couplings, making it a popular choice for various applications. Here are some of the key advantages:

- Torsional Flexibility: Diaphragm couplings provide excellent torsional flexibility, allowing them to compensate for angular, parallel, and axial misalignment between shafts. This flexibility helps in reducing stress on connected equipment and extends their lifespan.

- No Backlash: Unlike some other couplings, diaphragm couplings have no backlash, which means there is no play or free movement between the connected shafts. This characteristic makes them suitable for applications that require precise and accurate motion transmission.

- No Lubrication: Diaphragm couplings are typically maintenance-free since they do not require any lubrication. This reduces the overall maintenance costs and simplifies the operation of the mechanical system.

- High Torque Capacity: Despite their flexible design, diaphragm couplings can handle high torque loads efficiently. This makes them suitable for heavy-duty applications where high power transmission is required.

- Vibration Damping: The flexibility of the diaphragm in the coupling helps in absorbing and dampening vibrations, reducing the risk of damage to connected machinery and improving the overall system’s performance.

- Compact Size: Diaphragm couplings are generally compact and lightweight compared to some other coupling types. This feature makes them suitable for applications with limited space or weight constraints.

- Corrosion Resistance: Diaphragm couplings made from appropriate materials offer excellent corrosion resistance, making them suitable for use in harsh environments or industries where corrosion is a concern.

- Fail-Safe Design: Diaphragm couplings have a fail-safe design, meaning that in the event of diaphragm failure, they do not lead to catastrophic coupling failure. This enhances the safety and reliability of the mechanical system.

- Cost-Effectiveness: Considering their low maintenance requirements, long service life, and efficient torque transmission, diaphragm couplings offer a cost-effective solution for various applications.

In conclusion, diaphragm couplings provide significant advantages over other types of couplings, including torsional flexibility, zero backlash, no lubrication needs, high torque capacity, vibration damping, compact size, corrosion resistance, fail-safe design, and cost-effectiveness. These features make them a preferred choice in a wide range of mechanical systems and industrial applications.

editor by CX 2024-05-08