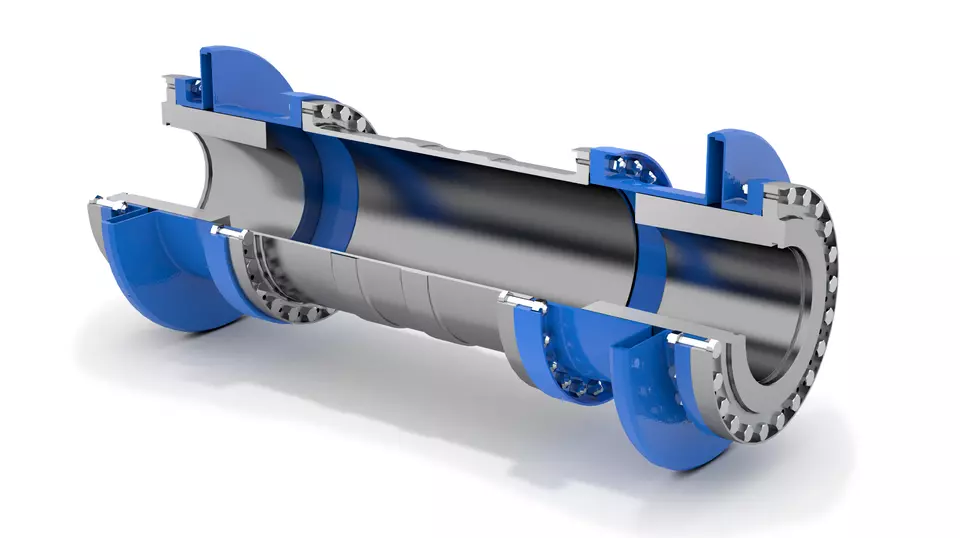

Product Description

The Manufacturer Supplies Coupling Rigid Screw Coupling Clamping Shell Double Diaphragm Servo Motor Aluminum Alloy Diaphragm Coupling

Detailed Photos

| brand | ever power |

| country of origin | china |

Application

Application of Aluminum Alloy Diaphragm Coupling

-

Machinery and Automation: Diaphragm couplings are used in various machinery and automation systems, such as CNC machines, robotic arms, printing presses, packaging equipment, and conveyor systems. These couplings provide accurate torque transmission, compensate for misalignment, and dampen vibrations, ensuring smooth and efficient operation.

-

Power Generation: Aluminum alloy diaphragm couplings are employed in power generation equipment, including generators, turbines, and pumps. They efficiently transmit torque between the driving and driven components while accommodating misalignment and torsional vibrations.

-

Aerospace and Aviation: Diaphragm couplings are utilized in aerospace and aviation applications, such as aircraft engines and auxiliary power units (APUs). Due to their lightweight construction and high torsional stiffness, aluminum alloy diaphragm couplings help reduce weight and ensure precise torque transmission in critical aerospace systems.

-

Oil and Gas Industry: Diaphragm couplings are commonly used in oil and gas exploration and production equipment, such as pumps, compressors, and drilling rigs. They provide reliable torque transmission, compensate for misalignment, and withstand harsh operating conditions in these demanding environments.

-

Motorsports: Aluminum alloy diaphragm couplings find applications in motorsports, particularly in high-performance racing cars and motorcycles. These couplings help transmit torque from the engine to the drivetrain while maintaining precision and handling the demands of high-speed and high-power applications.

-

Marine Industry: Diaphragm couplings are utilized in various marine applications, including propulsion systems, marine generators, and marine pumps. They provide efficient torque transfer and compensate for misalignment and shaft deflection, ensuring reliable performance in marine environments.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Diaphragm Couplings Compensate for Axial, Angular, and Parallel Misalignments?

Yes, diaphragm couplings are designed to compensate for axial, angular, and parallel misalignments between two shafts, making them highly flexible and versatile for various mechanical systems. Here’s how diaphragm couplings handle each type of misalignment:

- Axial Misalignment:

- Angular Misalignment:

- Parallel Misalignment:

Diaphragm couplings can accommodate a limited amount of axial misalignment, which refers to the offset between the rotational axes of the connected shafts. The flexible diaphragm allows for a slight axial movement, ensuring that the coupling can handle minor misalignments without introducing significant additional stresses to the shafts or coupling components.

Diaphragm couplings can also compensate for angular misalignment, which occurs when the rotational axes of the shafts are not parallel. The flexibility of the diaphragm allows it to flex and bend, allowing the coupling to transmit torque efficiently even when the shafts are at an angle to each other.

Parallel misalignment refers to the lateral offset between the shafts in the same plane. Diaphragm couplings can accommodate a certain degree of parallel misalignment due to the flexibility of the diaphragm. This feature helps prevent binding or premature wear on the coupling and connected machinery.

Diaphragm couplings are specifically designed to handle misalignments while maintaining smooth and efficient torque transmission. The flexibility of the diaphragm allows it to compensate for these misalignments, reducing stress on the connected equipment and providing a more reliable power transmission solution.

It’s important to note that while diaphragm couplings can accommodate some misalignments, there are limits to the amount of misalignment they can compensate for. Excessive misalignments beyond the coupling’s specified tolerances can lead to reduced coupling performance, premature wear, and potential failure. Therefore, it is essential to follow the manufacturer’s guidelines and recommendations for allowable misalignments to ensure optimal performance and longevity of the diaphragm coupling in a given application.

Maintenance Requirements for Diaphragm Couplings to Extend Their Lifespan

Proper maintenance is essential to extend the lifespan and ensure optimal performance of diaphragm couplings. Regular inspection and servicing can help identify potential issues early, prevent unexpected failures, and maximize the longevity of the coupling. Here are the key maintenance requirements for diaphragm couplings:

- Regular Inspections:

- Lubrication:

- Torque and Temperature Monitoring:

- Alignment Checks:

- Environmental Considerations:

- Replace Worn or Damaged Parts:

- Follow Manufacturer’s Guidelines:

- Operator Training:

Perform routine visual inspections of the diaphragm coupling to check for signs of wear, damage, or misalignment. Look for cracks, corrosion, or any visible deformation in the diaphragm and other coupling components. Regular inspections help catch potential problems early on.

Some diaphragm couplings may require periodic lubrication, depending on the design and materials used. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant to ensure smooth operation and reduce friction between moving parts.

In critical applications or where high torque is involved, consider implementing torque monitoring systems to track the torque levels during operation. Similarly, monitor the operating temperature of the coupling to ensure it stays within the acceptable range. Monitoring these parameters can help detect abnormal conditions that may lead to premature wear or failure.

Periodically check the alignment of the connected shafts to ensure they remain within the specified tolerances. Misalignment can cause additional stress on the diaphragm coupling and lead to accelerated wear. If misalignment is detected, it should be corrected promptly.

Consider the operating environment of the diaphragm coupling. In harsh or corrosive environments, take appropriate measures to protect the coupling from exposure to damaging elements. This may include using corrosion-resistant materials or applying protective coatings.

If during inspections, any parts of the diaphragm coupling are found to be worn, damaged, or beyond their recommended service life, they should be replaced promptly with genuine spare parts from the manufacturer. Using non-standard or substandard parts can compromise the performance and safety of the coupling.

Adhere to the maintenance recommendations provided by the diaphragm coupling manufacturer. They often include specific guidelines on inspection intervals, torque values, and other maintenance procedures tailored to the particular coupling model.

Ensure that operators and maintenance personnel receive proper training on the inspection and maintenance procedures of the diaphragm coupling. Trained personnel can identify potential issues and perform maintenance tasks correctly, contributing to the longevity of the coupling.

By following these maintenance requirements and performing regular upkeep, diaphragm couplings can have an extended lifespan, providing reliable and efficient power transmission for various mechanical systems.

Advantages of Diaphragm Coupling Compared to Other Types of Couplings

A diaphragm coupling offers several advantages over other types of couplings, making it a popular choice for various applications. Here are some of the key advantages:

- Torsional Flexibility: Diaphragm couplings provide excellent torsional flexibility, allowing them to compensate for angular, parallel, and axial misalignment between shafts. This flexibility helps in reducing stress on connected equipment and extends their lifespan.

- No Backlash: Unlike some other couplings, diaphragm couplings have no backlash, which means there is no play or free movement between the connected shafts. This characteristic makes them suitable for applications that require precise and accurate motion transmission.

- No Lubrication: Diaphragm couplings are typically maintenance-free since they do not require any lubrication. This reduces the overall maintenance costs and simplifies the operation of the mechanical system.

- High Torque Capacity: Despite their flexible design, diaphragm couplings can handle high torque loads efficiently. This makes them suitable for heavy-duty applications where high power transmission is required.

- Vibration Damping: The flexibility of the diaphragm in the coupling helps in absorbing and dampening vibrations, reducing the risk of damage to connected machinery and improving the overall system’s performance.

- Compact Size: Diaphragm couplings are generally compact and lightweight compared to some other coupling types. This feature makes them suitable for applications with limited space or weight constraints.

- Corrosion Resistance: Diaphragm couplings made from appropriate materials offer excellent corrosion resistance, making them suitable for use in harsh environments or industries where corrosion is a concern.

- Fail-Safe Design: Diaphragm couplings have a fail-safe design, meaning that in the event of diaphragm failure, they do not lead to catastrophic coupling failure. This enhances the safety and reliability of the mechanical system.

- Cost-Effectiveness: Considering their low maintenance requirements, long service life, and efficient torque transmission, diaphragm couplings offer a cost-effective solution for various applications.

In conclusion, diaphragm couplings provide significant advantages over other types of couplings, including torsional flexibility, zero backlash, no lubrication needs, high torque capacity, vibration damping, compact size, corrosion resistance, fail-safe design, and cost-effectiveness. These features make them a preferred choice in a wide range of mechanical systems and industrial applications.

editor by CX 2024-02-13