Product Description

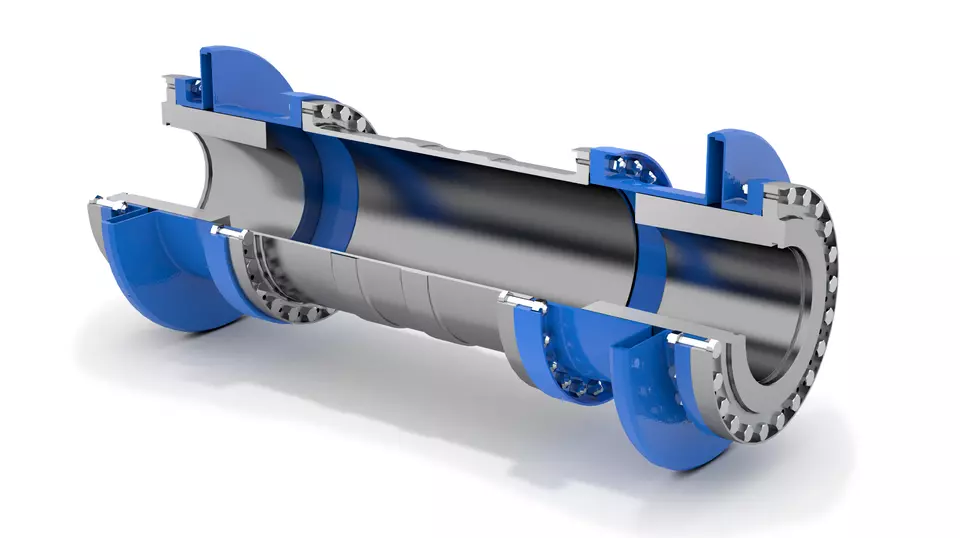

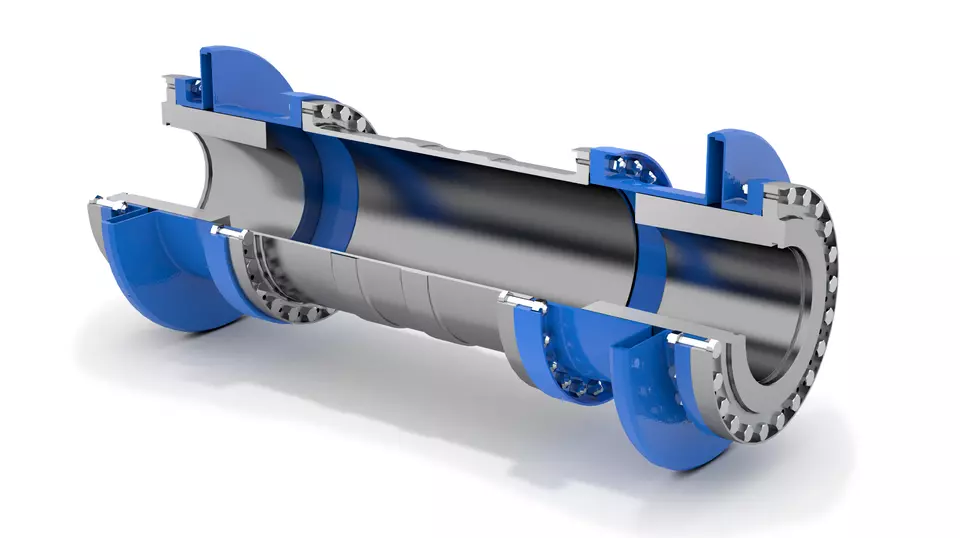

JM Flexible Double Disc Coupler Diaphragm Coupling

Description:

JM High Quality Double Disc Flexible Diaphragm Coupling compensates for 2 axis misalignment, strong radial displacement, small flexibility and large axial displacement, allowing axial, radial and angular displacement. The JMIIJ High Quality Double Disc Flexible Diaphragm Coupling are different from the common diaphragm couplings. They not only connect the intermediate shaft, extend the transmission distance, but also have 2 diaphragms to increase the flexibility compensation amount, so they are also called double diaphragm couplings.

Paramters:

Features:

JM High Quality Double Disc Flexible Diaphragm Coupling can accurately transfer speed, operation without rotation difference, and can be used for precision mechanical transmission. The transmission efficiency is up to 99.86% in the transmission, especially for medium and high speed high power transmission. It is simple in structure, light in weight, small in volume and convenient in assembly and dismantling. Do not have to move the machine to install, without lubrication. Adapt to the high temperature (-80+300) and the bad environment work, and can be operated safely under the condition of shock and vibration. It has obvious shock absorption, no noise, no wear and tear.

Details:

Packing & Delivery:

Inner Packing: PP bag with carton;

Outer Packing: Wooden case;

Shipment: 20-30 days CHINAMFG receiving the deposit.

About us:

HangZhou CHINAMFG machinery technology Co., Ltd is an industry transmission solutions manufacuturer and service provider.

We offer 1 stop solution for power transmission products for different factories, such as chemicals, energy, material handling, environmental, extraction, pulp and paper, steel and metal, food and beverage, and construction industries.

We supply: Customised gears, Small gearmotors, Industrial gearboxes, Motors, Brand product sourcing.

Our industrial Gear, Gearbox, gearmotor and motor are sold to more than 30 countries. High quality, good price, in time response and sincere service are our value and promises. We aim at making happy cooperation with our customers, bring them reliable and comfortable service. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can Diaphragm Couplings Operate in High-Temperature or Corrosive Environments?

Yes, diaphragm couplings can be designed and manufactured to operate in high-temperature or corrosive environments, depending on the materials used in their construction. Here’s how diaphragm couplings can handle these challenging conditions:

High-Temperature Environments:

For applications involving high temperatures, manufacturers can use heat-resistant materials for the diaphragm and other coupling components. Some common high-temperature materials include:

- Stainless Steel Alloys: Certain stainless steel alloys, such as Inconel or Hastelloy, are known for their excellent high-temperature properties. These alloys can withstand elevated temperatures without significant deformation or loss of strength.

- Titanium: Titanium is another material that offers good heat resistance. It is lightweight, strong, and can operate at elevated temperatures, making it suitable for certain high-temperature applications.

- Ceramic Coatings: In some cases, manufacturers apply ceramic coatings to the diaphragm or other components to enhance their heat resistance and protect them from thermal degradation.

By using these high-temperature materials, diaphragm couplings can maintain their performance and integrity in environments with extreme heat, such as steel mills, heat treatment furnaces, and power generation plants.

Corrosive Environments:

Diaphragm couplings can also be designed to withstand corrosive environments by using materials that resist chemical attacks. Some options for corrosive environments include:

- Corrosion-Resistant Stainless Steel: Certain stainless steel alloys, like 316L or Duplex stainless steel, offer excellent resistance to corrosion from chemicals and corrosive agents.

- Specialty Coatings: Manufacturers may apply coatings or platings to the coupling components to provide an additional layer of protection against corrosion.

- Non-Metallic Materials: In some cases, non-metallic materials like PTFE (Teflon) or polypropylene may be used for the diaphragm and other components, as they are highly resistant to chemical corrosion.

By using these corrosion-resistant materials, diaphragm couplings can be used in applications such as chemical processing, wastewater treatment, marine environments, and other situations where exposure to corrosive substances is common.

In summary, diaphragm couplings can be engineered to operate in high-temperature or corrosive environments by selecting appropriate materials that offer the necessary heat resistance and corrosion resistance. When specifying a diaphragm coupling for such applications, it is crucial to consider the specific environmental conditions to ensure the coupling’s long-term performance and reliability.

How Diaphragm Couplings Handle Torsional Stiffness and Dynamic Balancing in Rotating Machinery

Diaphragm couplings are engineered to address two critical aspects of rotating machinery: torsional stiffness and dynamic balancing. These features ensure efficient power transmission and smooth operation in various industrial applications. Here’s how diaphragm couplings achieve torsional stiffness and dynamic balancing:

- Torsional Stiffness:

- Dynamic Balancing:

Torsional stiffness refers to the ability of a coupling to resist angular deflection or twisting when torque is applied. Diaphragm couplings are designed with a flexible diaphragm made of a high-strength metallic material. This diaphragm connects the two shafts and transmits torque between them.

The design of the diaphragm allows it to flex slightly under load while maintaining its integrity. This controlled flexibility ensures that the diaphragm coupling can handle misalignments and accommodate minor variations in the alignment of the shafts. Despite this flexibility, diaphragm couplings offer high torsional stiffness, ensuring efficient power transmission without significant energy losses due to deformation.

The combination of flexibility and torsional stiffness allows diaphragm couplings to absorb shocks and vibrations, which can occur during start-up or during sudden changes in load. As a result, diaphragm couplings help protect the connected machinery from damage caused by torque fluctuations and torsional vibrations.

Dynamic balancing is crucial to prevent excessive vibrations in rotating machinery, which can lead to premature wear, increased stress on components, and reduced equipment lifespan. Imbalanced rotating parts can cause oscillations and resonance, adversely affecting the overall performance of the system.

Diaphragm couplings are inherently well-balanced due to their symmetrical design and the equal distribution of mass around the center of rotation. This balanced configuration minimizes the generation of vibrations during operation. Additionally, the flexibility of the diaphragm helps dampen any residual vibrations that may arise, further contributing to the dynamic balancing of the system.

In cases where extremely high precision is required, diaphragm couplings can undergo additional balancing processes during manufacturing to fine-tune their dynamic characteristics. This process ensures that the coupling operates optimally even at high rotational speeds.

By efficiently handling torsional stiffness and dynamic balancing, diaphragm couplings contribute to the smooth and reliable operation of rotating machinery across various industries. Their ability to handle misalignments, dampen vibrations, and transmit torque accurately makes them an essential component in many critical applications, such as pumps, compressors, turbines, and more.

Are There Any Industry Standards or Certifications for Diaphragm Couplings?

Yes, there are industry standards and certifications that apply to diaphragm couplings, ensuring their quality, performance, and safety. Some of the notable standards and certifications include:

- American Petroleum Institute (API) Standards: API provides standards for various equipment and components used in the oil and gas industry. For diaphragm couplings used in oil and gas applications, compliance with API standards ensures that the couplings meet specific requirements and are suitable for use in demanding environments.

- American Gear Manufacturers Association (AGMA) Standards: AGMA sets standards for various types of couplings, including diaphragm couplings. These standards cover design considerations, materials, performance, and safety factors, ensuring that couplings adhere to industry best practices.

- International Organization for Standardization (ISO) Standards: ISO has several standards relevant to couplings in general, which can also apply to diaphragm couplings. ISO standards ensure global consistency in terms of design, manufacturing, and performance criteria.

- European Conformity (CE) Marking: Diaphragm couplings intended for sale within the European Economic Area (EEA) must bear the CE marking, indicating that they comply with relevant European Union (EU) directives, including safety and environmental requirements.

- American National Standards Institute (ANSI) Standards: ANSI sets standards for various industrial equipment, including couplings. ANSI standards provide guidelines for design, materials, and performance, ensuring safe and reliable operation.

- Occupational Safety and Health Administration (OSHA) Compliance: Although not a specific certification for diaphragm couplings, compliance with OSHA regulations is essential to ensure the safety of workers who operate and maintain equipment with diaphragm couplings.

Manufacturers of diaphragm couplings often seek these certifications and comply with relevant industry standards to demonstrate the quality and reliability of their products. Customers and end-users can look for these certifications and standards compliance when selecting diaphragm couplings for their applications, as it provides assurance of the coupling’s performance and adherence to safety requirements.

editor by CX 2024-04-09