Product Description

Diaphragm Coupling Single Double Membrane Hydraulic Fluid Drive Roller Chain Spider Flexible Jaw Rubber Flexible Jaw Flange Coupling

Product Description

Application of Diaphragm Coupling

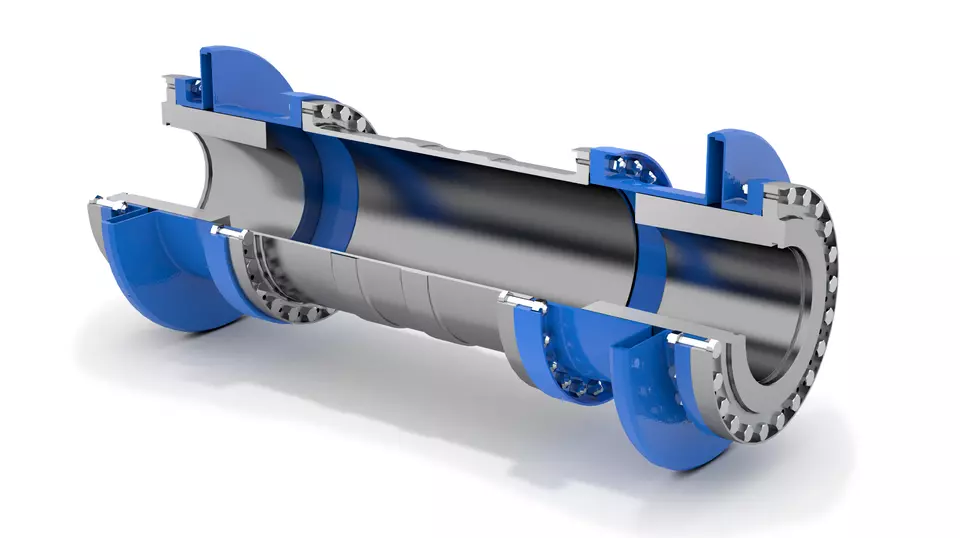

Diaphragm couplings are flexible couplings that consist of 2 hubs connected by a diaphragm, typically made of metal. These couplings provide torque transmission while accommodating misalignment between the connected shafts. Here are some typical applications of diaphragm couplings:

1. Power Generation: Diaphragm couplings are used in power generation applications, including gas turbines, steam turbines, diesel generators, and wind turbines. They transmit torque between the turbine or generator shaft and the driven equipment, such as pumps, compressors, and electrical generators. Diaphragm couplings accommodate misalignment caused by thermal expansion, shaft deflection, and other factors, ensuring efficient power transmission.

2. Industrial Machinery: Diaphragm couplings find application in various industrial machinery, including pumps, compressors, fans, blowers, and mixers. They provide torque transmission between the motor or engine shaft and the driven equipment, allowing for misalignment compensation and vibration isolation. Diaphragm couplings are often used in heavy-duty and high-speed applications where precise torque transmission and misalignment accommodation are essential.

3. Printing and Packaging: Diaphragm couplings are employed in printing and packaging machinery, such as printing presses, laminators, and slitters. They transmit torque between the motor or engine and the rollers or cylinders in the printing or packaging. Diaphragm couplings accommodate misalignment caused by roller deflection, thermal expansion, or other factors, ensuring accurate and reliable operation.

4. Metalworking Equipment: Diaphragm couplings are commonly used in metalworking machinery, including lathes, milling machines, grinding machines, and CNC machines. They transmit torque between the motor or engine and the cutting tools or workpieces. Diaphragm couplings compensate for misalignment due to thermal expansion or positional errors, enabling precise machining and improving tool life.

5. Petrochemical and Oil & Gas Industry: Diaphragm couplings are employed in various applications in the petrochemical and oil & gas industries. They are used in pumps, compressors, turbines, and other equipment to transmit torque while accommodating misalignment caused by temperature variations, shaft deflection, or seismic events. Diaphragm couplings help ensure reliable and efficient operation in demanding environments.

6. Marine and Offshore Applications: Diaphragm couplings find application in the marine and offshore industry. They are used in propulsion systems, power generators, and machinery on ships, offshore platforms, and drilling rigs. Diaphragm couplings transmit torque between the engine or motor and the driven equipment, compensating for misalignment due to hull deflection, shaft misalignment, or vibrations.

7. Automotive and Racing: Diaphragm couplings are used in high-performance automotive applications, such as racing cars and street vehicles. They are used in drivetrain systems to transmit torque while accommodating misalignment and torsional vibrations. Diaphragm couplings help improve drivetrain performance, reduce vibrations, and enhance overall vehicle handling.

These are just a few examples of the applications of diaphragm couplings. Their ability to transmit torque while accommodating misalignment makes them suitable for various industries and systems where flexible and reliable power transmission is required.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Proper Installation of a Diaphragm Coupling for Optimal Performance and Reliability

Proper installation of a diaphragm coupling is essential to ensure its optimal performance and reliability. Here are the steps to follow for a successful installation:

- Inspect the Coupling:

- Shaft Preparation:

- Hub Alignment:

- Tighten Fasteners Correctly:

- Check Runout and Balance:

- Lubrication (if applicable):

- Regular Maintenance:

Before installation, thoroughly inspect the diaphragm coupling for any damage, wear, or deformation. Check for proper alignment of the hubs and make sure they are clean and free from any debris or contaminants.

Ensure that the shafts to be connected are clean, smooth, and free of any burrs or rough edges that could damage the coupling or affect its performance. If necessary, use appropriate tools to deburr and polish the shaft ends.

Align the two hubs of the diaphragm coupling carefully with the shafts. Misalignment during installation can cause premature wear and failure of the coupling. Use alignment tools like dial indicators or laser alignment systems to achieve accurate shaft alignment.

Use the specified torque values and tightening sequence provided by the coupling manufacturer to tighten the fasteners securely. Over-tightening can lead to stress concentrations, while under-tightening can result in loose connections and coupling slippage.

After installation, check the runout of the coupling assembly to ensure that it rotates without wobbling or eccentricity. Also, verify that the coupling is properly balanced to prevent excessive vibrations during operation.

Some diaphragm couplings require lubrication for smooth operation. If lubrication is necessary, follow the manufacturer’s guidelines and use the recommended lubricant to prevent premature wear and reduce friction.

To ensure continued optimal performance, schedule regular inspections and maintenance for the diaphragm coupling. Check for signs of wear, misalignment, or damage, and replace the coupling if necessary. Regular maintenance can help identify potential issues early and prevent unexpected failures.

Following these installation and maintenance guidelines will help maximize the life and performance of the diaphragm coupling, ensuring reliable and efficient operation in various mechanical systems and applications.

Maintenance Requirements for Diaphragm Couplings to Extend Their Lifespan

Proper maintenance is essential to extend the lifespan and ensure optimal performance of diaphragm couplings. Regular inspection and servicing can help identify potential issues early, prevent unexpected failures, and maximize the longevity of the coupling. Here are the key maintenance requirements for diaphragm couplings:

- Regular Inspections:

- Lubrication:

- Torque and Temperature Monitoring:

- Alignment Checks:

- Environmental Considerations:

- Replace Worn or Damaged Parts:

- Follow Manufacturer’s Guidelines:

- Operator Training:

Perform routine visual inspections of the diaphragm coupling to check for signs of wear, damage, or misalignment. Look for cracks, corrosion, or any visible deformation in the diaphragm and other coupling components. Regular inspections help catch potential problems early on.

Some diaphragm couplings may require periodic lubrication, depending on the design and materials used. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant to ensure smooth operation and reduce friction between moving parts.

In critical applications or where high torque is involved, consider implementing torque monitoring systems to track the torque levels during operation. Similarly, monitor the operating temperature of the coupling to ensure it stays within the acceptable range. Monitoring these parameters can help detect abnormal conditions that may lead to premature wear or failure.

Periodically check the alignment of the connected shafts to ensure they remain within the specified tolerances. Misalignment can cause additional stress on the diaphragm coupling and lead to accelerated wear. If misalignment is detected, it should be corrected promptly.

Consider the operating environment of the diaphragm coupling. In harsh or corrosive environments, take appropriate measures to protect the coupling from exposure to damaging elements. This may include using corrosion-resistant materials or applying protective coatings.

If during inspections, any parts of the diaphragm coupling are found to be worn, damaged, or beyond their recommended service life, they should be replaced promptly with genuine spare parts from the manufacturer. Using non-standard or substandard parts can compromise the performance and safety of the coupling.

Adhere to the maintenance recommendations provided by the diaphragm coupling manufacturer. They often include specific guidelines on inspection intervals, torque values, and other maintenance procedures tailored to the particular coupling model.

Ensure that operators and maintenance personnel receive proper training on the inspection and maintenance procedures of the diaphragm coupling. Trained personnel can identify potential issues and perform maintenance tasks correctly, contributing to the longevity of the coupling.

By following these maintenance requirements and performing regular upkeep, diaphragm couplings can have an extended lifespan, providing reliable and efficient power transmission for various mechanical systems.

Advantages of Diaphragm Coupling Compared to Other Types of Couplings

A diaphragm coupling offers several advantages over other types of couplings, making it a popular choice for various applications. Here are some of the key advantages:

- Torsional Flexibility: Diaphragm couplings provide excellent torsional flexibility, allowing them to compensate for angular, parallel, and axial misalignment between shafts. This flexibility helps in reducing stress on connected equipment and extends their lifespan.

- No Backlash: Unlike some other couplings, diaphragm couplings have no backlash, which means there is no play or free movement between the connected shafts. This characteristic makes them suitable for applications that require precise and accurate motion transmission.

- No Lubrication: Diaphragm couplings are typically maintenance-free since they do not require any lubrication. This reduces the overall maintenance costs and simplifies the operation of the mechanical system.

- High Torque Capacity: Despite their flexible design, diaphragm couplings can handle high torque loads efficiently. This makes them suitable for heavy-duty applications where high power transmission is required.

- Vibration Damping: The flexibility of the diaphragm in the coupling helps in absorbing and dampening vibrations, reducing the risk of damage to connected machinery and improving the overall system’s performance.

- Compact Size: Diaphragm couplings are generally compact and lightweight compared to some other coupling types. This feature makes them suitable for applications with limited space or weight constraints.

- Corrosion Resistance: Diaphragm couplings made from appropriate materials offer excellent corrosion resistance, making them suitable for use in harsh environments or industries where corrosion is a concern.

- Fail-Safe Design: Diaphragm couplings have a fail-safe design, meaning that in the event of diaphragm failure, they do not lead to catastrophic coupling failure. This enhances the safety and reliability of the mechanical system.

- Cost-Effectiveness: Considering their low maintenance requirements, long service life, and efficient torque transmission, diaphragm couplings offer a cost-effective solution for various applications.

In conclusion, diaphragm couplings provide significant advantages over other types of couplings, including torsional flexibility, zero backlash, no lubrication needs, high torque capacity, vibration damping, compact size, corrosion resistance, fail-safe design, and cost-effectiveness. These features make them a preferred choice in a wide range of mechanical systems and industrial applications.

editor by CX 2024-04-09