Product Description

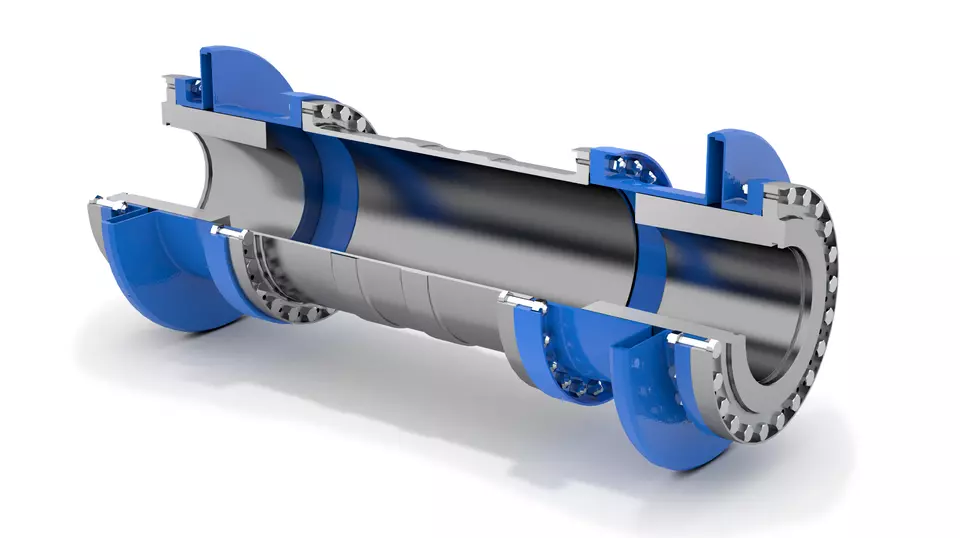

GL Aluminum alloy double diaphragm clamping coupling

Description of GL Aluminum alloy double diaphragm clamping coupling

>High torque rigidity, can accurately control the rotation of the shaft, can carry out high-precision control

>Designed for servo and stepping motor

>No gap between the shaft and sleeve connection, general for positive and negative rotation

>Low inertia, suitable for high speed operation

>The diaphragm is made of spring steel with excellent fatigue resistance

>Fastening method of clamping screw

Dimensions of GL Aluminum alloy double diaphragm clamping coupling

| model parameter | common bore diameter d1,d2 | ΦD | L | LF | LP | d3 | S | F | M | tightening screw torque (N.M) |

| GL-19X27 | 3,4,5,6,6.35,7,8 | 19 | 27 | 9.1 | 5.2 | Φ9 | 1.8 | 3.3 | M2.5 | 1 |

| GL-26X35 | 5,6,6.35,7,8,9,9.525,10,11,12,14 | 26 | 35 | 11.65 | 6.5 | Φ12.5 | 2.6 | 3.9 | M3 | 1.5 |

| GL-32X41 | 5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15, | 32 | 45 | 12.25 | 9.5 | Φ15 | 3.5 | 3.85 | M3 | 1.5 |

| GL-34X45 | 5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15,16 | 34 | 45 | 14.25 | 9.5 | Φ16 | 4.5 | 4.85 | M4 | 2.5 |

| GL-39X50 | 8,9,9.525,10,11,12,12.7,14,15,16,17,18,19 | 39 | 50 | 14.9 | 11.2 | Φ9.3 | 4.5 | 5 | M4 | 2.5 |

| GL-44X50 | 8,9,9.525,10,11,12,12.7,14,15,16,17,18,19,20,22 | 44 | 50 | 14.9 | 11.2 | Φ2.5 | 4.5 | 5 | M4 | 2.5 |

| GL-50X63 | 8,9,9.525,10,11,12,12.7,14,15,16,17,18,19,20,22,24,25 | 50 | 63 | 20.6 | 12.5 | Φ23 | 4.8 | 6 | M5 | 7 |

| GL-56X64 | 10,12,14,15,16,17,18,19,20,22,24,25,28,30,32 | 56 | 64 | 19.75 | 13.5 | Φ2.5 | 5.5 | 6.4 | M5 | 7 |

| GL-68X75 | 12,14,15,16,17,18,19,20,22,24,25,28,30,32,35,38 | 68 | 75 | 23.35 | 15.7 | Φ38.3 | 6.3 | 7.7 | M6 | 12 |

| GL-82X98 | 17,18,19,20,22,24,25,28,30,32,35,38,40,42 | 82 | 98 | 30 | 22 | Φ45.5 | 8 | 9.7 | M8 | 20 |

| model parameter | Rated torque (N.M)* |

allowable eccentricity (mm)* |

allowable deflection angle (°)* |

allowable axial deviation (mm)* |

maximum speed rpm |

static torsional stiffness (N.M/rad) |

moment of inertia (Kg.M2) |

Material of shaft sleeve | Material of shrapnel | surface treatment | weight (g) |

| GL-19X27 | 1 | 0.12 | 1.5 | ±0.18 | 10000 | 170 | 9.1×10-7 | High strength aluminum alloy | SUS304Spring steel | Anodizing treatment | 14.6 |

| GL-26X35 | 1.5 | 0.15 | 1.5 | ±0.3 | 10000 | 820 | 3.0×10-6 | 37 | |||

| GL-32X41 | 2 | 0.17 | 1.5 | ±0.36 | 10000 | 1750 | 1.0×10-5 | 67 | |||

| GL-34X45 | 3 | 0.17 | 1.5 | ±0.36 | 10000 | 1860 | 1.1×10-5 | 77 | |||

| GL-39X50 | 6 | 0.22 | 1.5 | ±0.45 | 10000 | 2860 | 3.0×10-5 | 118 | |||

| GL-44X50 | 9 | 0.22 | 1.5 | ±0.54 | 10000 | 3300 | 3.8×10-5 | 144 | |||

| GL-50X63 | 18 | 0.1 | 1.5 | ±0.54 | 10000 | 3300 | 3.0×10-5 | 235 | |||

| GL-56X64 | 25 | 0.27 | 1.5 | ±0.72 | 10000 | 9480 | 1.6×10-4 | 318 | |||

| GL-68X75 | 60 | 0.31 | 1.5 | ±0.8 | 9000 | 19000 | 2.0×10-4 | 492 | |||

| GL-82X98 | 100 | 0.55 | 1.5 | ±0.8 | 8000 | 28450 | 2.5×10-4 | 1013 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Materials Used to Manufacture Diaphragm Couplings and Their Impact on Performance

Diaphragm couplings are manufactured using various materials, and the choice of material significantly impacts their performance in different applications. Here are some common materials used in diaphragm couplings and their impact on performance:

- Metallic Alloys:

- High-Temperature Alloys:

- Titanium:

- Elastomers:

- Non-Metallic Materials:

Stainless steel and other high-strength metallic alloys are widely used in diaphragm couplings. These materials offer excellent durability, high torsional stiffness, and resistance to wear and fatigue. They are well-suited for high-torque applications and environments with demanding operating conditions.

In applications where diaphragm couplings are exposed to elevated temperatures, specialized high-temperature alloys like Inconel and Hastelloy are used. These alloys can withstand extreme heat without losing their mechanical properties, making them ideal for use in industries such as steel processing and power generation.

Titanium is favored for its lightweight and excellent corrosion resistance. Diaphragm couplings made from titanium are commonly used in aerospace and marine applications where weight reduction and resistance to corrosive environments are critical.

For certain applications that require vibration dampening and shock absorption, diaphragm couplings can be manufactured with elastomeric materials like rubber or urethane. These materials help reduce transmitted vibrations and can be found in pumps, compressors, and automotive drivetrain systems.

In situations where electrical isolation or non-magnetic properties are necessary, non-metallic materials like PTFE (Teflon) or polypropylene may be used. These materials are also highly resistant to chemical corrosion, making them suitable for certain chemical processing and semiconductor applications.

The choice of material impacts several aspects of diaphragm coupling performance, including:

- Torsional Stiffness: Metallic alloys and high-temperature materials provide high torsional stiffness, ensuring efficient torque transmission and accuracy in motion control applications.

- Corrosion Resistance: The selection of corrosion-resistant materials is crucial in applications where diaphragm couplings are exposed to corrosive environments, such as in marine or chemical industries.

- Temperature Resistance: High-temperature alloys enable diaphragm couplings to operate effectively in environments with elevated temperatures, such as steel processing or power generation plants.

- Weight: Materials like titanium offer lightweight advantages, making diaphragm couplings suitable for aerospace and other weight-sensitive applications.

- Vibration Damping: Elastomeric materials provide excellent vibration dampening properties, reducing vibrations and noise in certain applications.

Manufacturers carefully select the appropriate material based on the specific requirements of the application to ensure optimal performance and reliability of the diaphragm coupling in a wide range of industries.

How Diaphragm Couplings Handle Torsional Stiffness and Dynamic Balancing in Rotating Machinery

Diaphragm couplings are engineered to address two critical aspects of rotating machinery: torsional stiffness and dynamic balancing. These features ensure efficient power transmission and smooth operation in various industrial applications. Here’s how diaphragm couplings achieve torsional stiffness and dynamic balancing:

- Torsional Stiffness:

- Dynamic Balancing:

Torsional stiffness refers to the ability of a coupling to resist angular deflection or twisting when torque is applied. Diaphragm couplings are designed with a flexible diaphragm made of a high-strength metallic material. This diaphragm connects the two shafts and transmits torque between them.

The design of the diaphragm allows it to flex slightly under load while maintaining its integrity. This controlled flexibility ensures that the diaphragm coupling can handle misalignments and accommodate minor variations in the alignment of the shafts. Despite this flexibility, diaphragm couplings offer high torsional stiffness, ensuring efficient power transmission without significant energy losses due to deformation.

The combination of flexibility and torsional stiffness allows diaphragm couplings to absorb shocks and vibrations, which can occur during start-up or during sudden changes in load. As a result, diaphragm couplings help protect the connected machinery from damage caused by torque fluctuations and torsional vibrations.

Dynamic balancing is crucial to prevent excessive vibrations in rotating machinery, which can lead to premature wear, increased stress on components, and reduced equipment lifespan. Imbalanced rotating parts can cause oscillations and resonance, adversely affecting the overall performance of the system.

Diaphragm couplings are inherently well-balanced due to their symmetrical design and the equal distribution of mass around the center of rotation. This balanced configuration minimizes the generation of vibrations during operation. Additionally, the flexibility of the diaphragm helps dampen any residual vibrations that may arise, further contributing to the dynamic balancing of the system.

In cases where extremely high precision is required, diaphragm couplings can undergo additional balancing processes during manufacturing to fine-tune their dynamic characteristics. This process ensures that the coupling operates optimally even at high rotational speeds.

By efficiently handling torsional stiffness and dynamic balancing, diaphragm couplings contribute to the smooth and reliable operation of rotating machinery across various industries. Their ability to handle misalignments, dampen vibrations, and transmit torque accurately makes them an essential component in many critical applications, such as pumps, compressors, turbines, and more.

How Do Diaphragm Couplings Handle Misalignment Between Shafts and Reduce Vibrations?

Diaphragm couplings are designed to handle misalignment between shafts and reduce vibrations effectively. Here’s how they achieve these functionalities:

- Misalignment Handling: Diaphragm couplings can accommodate three types of misalignment: angular, parallel, and axial misalignment.

- Angular Misalignment: When the shafts are not perfectly aligned and have angular offset, the flexible diaphragm in the coupling can flex and bend, allowing for relative movement between the shafts without transmitting excessive torque loads or inducing stress on the machinery.

- Parallel Misalignment: In cases where the shafts have parallel misalignment (i.e., horizontal offset), the diaphragm can also flex and move laterally to accommodate the misalignment while maintaining a continuous connection between the two hubs.

- Axial Misalignment: Diaphragm couplings can also handle axial misalignment (i.e., axial displacement), as the flexible diaphragm can compress or elongate slightly to adjust for the axial movement of the shafts.

- Vibration Reduction: Diaphragm couplings are known for their ability to dampen vibrations, which helps in reducing vibration levels in the connected machinery and the overall mechanical system.

- Flexible Diaphragm: The key component that enables vibration reduction is the flexible diaphragm. As the diaphragm flexes in response to misalignment or torque loads, it absorbs and dissipates vibrations, preventing them from being transmitted through the coupling and into the system.

- Natural Frequency: The design of the diaphragm is tuned to have a specific natural frequency, which allows it to effectively dampen and attenuate vibrations within the desired range.

- Material Selection: The choice of material for the diaphragm is crucial in determining its vibration damping capabilities. Certain materials have better vibration-absorbing properties, making them ideal for use in diaphragm couplings.

In summary, diaphragm couplings handle misalignment between shafts by using the flexible diaphragm to accommodate angular, parallel, and axial misalignment. Additionally, they reduce vibrations by utilizing the same flexible diaphragm to dampen and absorb vibrations, enhancing the smooth operation and longevity of the connected machinery and mechanical systems.

editor by CX 2024-05-02