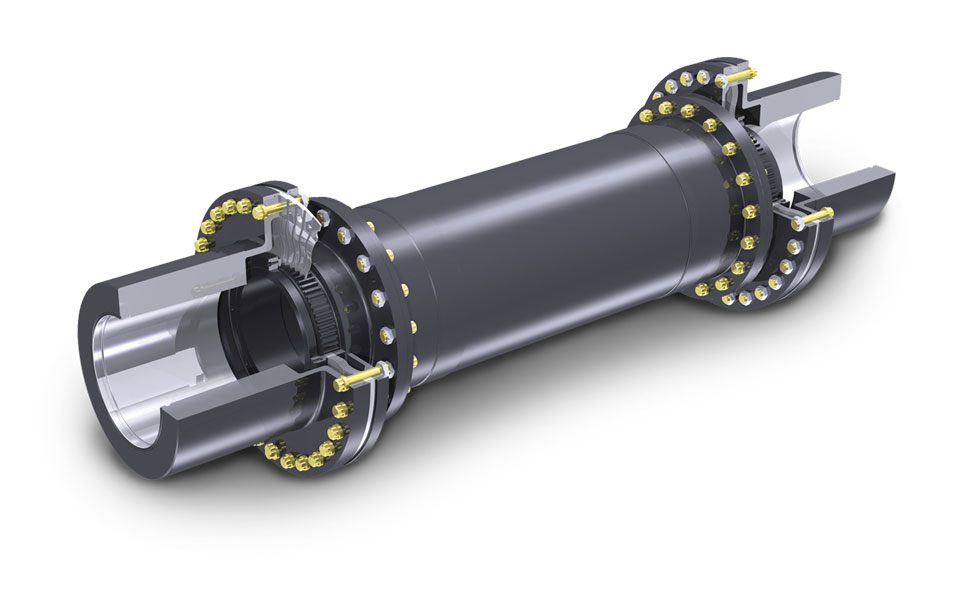

Introducing Diaphragm Coupling for Bottling Lines

Key Points:

- High-Quality Material

- Precision Engineering

- Flexible Design

- Low Maintenance

- High Torque Capacity

- Corrosion Resistance

Diaphragm couplings for bottling lines are made from durable and high-quality materials to ensure long-lasting performance and reliability.

These couplings are designed with precision engineering to provide smooth and efficient power transmission in bottling line machinery.

The flexible design of diaphragm couplings allows for misalignment compensation, reducing wear and tear on equipment.

With minimal moving parts, diaphragm couplings require low maintenance, making them ideal for bottling line applications.

Diaphragm couplings have a high torque capacity, making them suitable for heavy-duty bottling line operations.

These couplings are corrosion-resistant, ensuring longevity and reliability in harsh bottling line environments.

Features of Diaphragm Coupling for Bottling Lines:

- High-Quality Material

- Precision Machining

- Misalignment Compensation

- Low Maintenance

- High Torque Capacity

Manufactured from top-grade materials for durability and performance.

Engineered with precision for smooth power transmission in bottling line machinery.

Flexible design allows for misalignment compensation, reducing stress on equipment.

Minimal moving parts result in low maintenance requirements.

Capable of handling high torque loads for heavy-duty bottling line operations.

Application of Diaphragm Coupling for Bottling Lines:

Diaphragm couplings are ideal for bottling lines due to their flexible design, high torque capacity, and low maintenance requirements. These couplings can efficiently transmit power in bottling line machinery while compensating for misalignments. Their corrosion resistance ensures longevity in the harsh environments typically found in bottling facilities.

Advantages of Diaphragm Coupling for Bottling Lines:

- Longevity

- Efficiency

- Reliability

- Cost-Effectiveness

- Customization

High-quality materials and corrosion resistance ensure long-lasting performance.

Precision engineering results in smooth power transmission and reduced energy loss.

Low maintenance requirements and high torque capacity contribute to reliable operation.

Low maintenance and high durability make diaphragm couplings a cost-effective choice for bottling lines.

Diaphragm couplings can be customized to meet the specific requirements of bottling line machinery.

Installation Tips of Diaphragm Coupling for Bottling Lines:

- Ensure Proper Alignment

- Regular Maintenance

- Replace When Necessary

- Torque Specifications

- Consult Manufacturer Guidelines

Align the coupling properly to prevent premature wear and ensure efficient operation of bottling line machinery.

Perform regular maintenance checks to prolong the lifespan of the coupling and prevent unexpected failures.

Replace the diaphragm coupling when signs of wear or damage are detected to prevent costly downtime in bottling line operations.

Follow manufacturer’s torque specifications during installation to maintain the integrity of the coupling.

Refer to the manufacturer’s guidelines for proper installation procedures and maintenance recommendations.

About HZPT

HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production. With 16 years of experience, we offer high-quality products, customized solutions, and comprehensive quality inspection. Our couplings, including diaphragm couplings for bottling lines, are trusted by customers in Europe and the United States for their reliability and performance. Choose HZPT for superior products, exceptional service, and competitive prices.