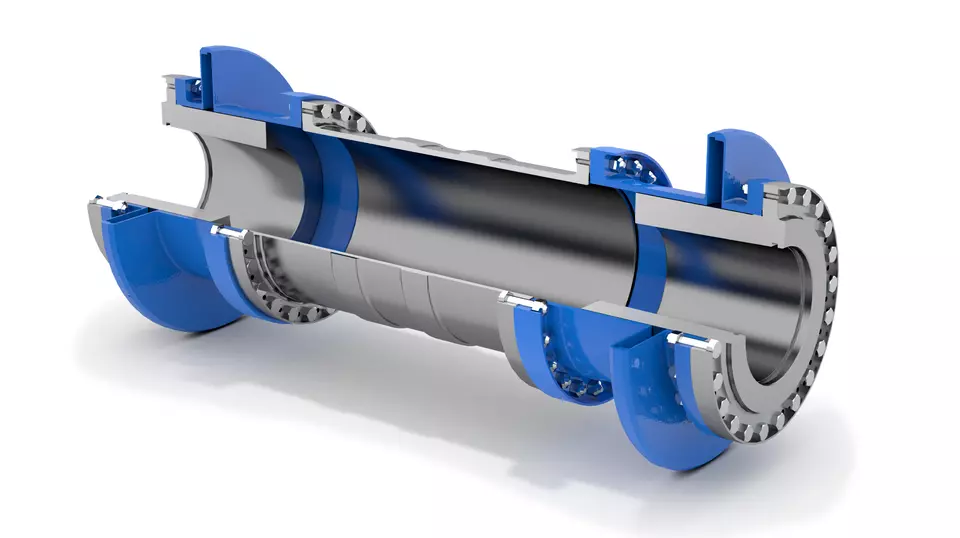

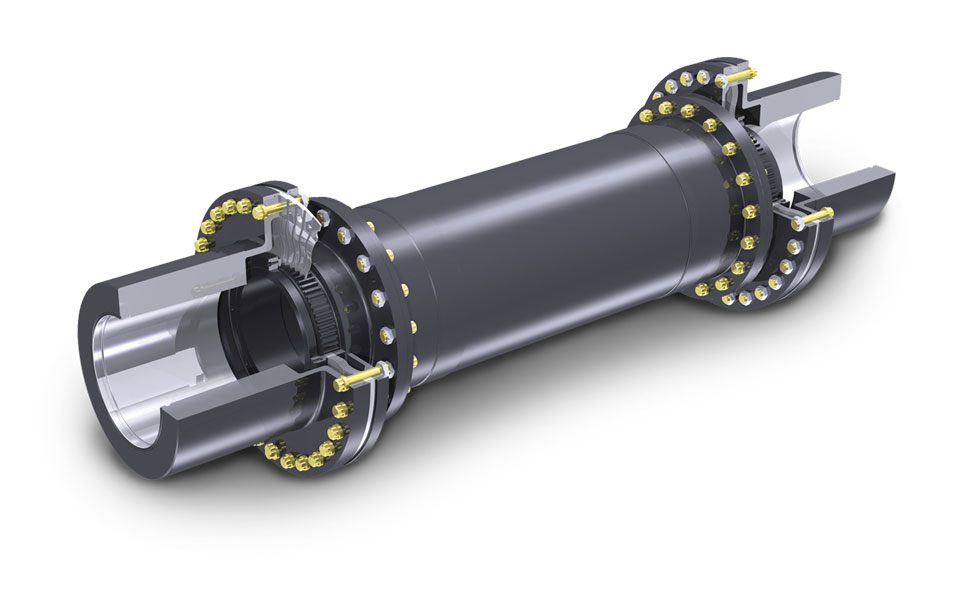

Introduction to NM Coupling for Canning Machinery

1. High-Quality Material

The NM coupling for canning machinery is made from premium materials that ensure durability and longevity.

2. Precision Engineering

Each NM coupling is meticulously designed and manufactured to meet the specific requirements of canning machinery.

3. Superior Flexibility

The NM coupling offers excellent flexibility, allowing for smooth operation and reduced wear and tear on machinery.

4. Easy Installation

With a user-friendly design, the NM coupling can be easily installed on canning machinery without the need for complex tools.

5. Cost-Effective Solution

Despite its high quality and performance, the NM coupling is offered at a competitive price point, making it a cost-effective choice for canning machinery.

6. Wide Application

The NM coupling is suitable for various types of canning machinery, providing versatile solutions for different production needs.

Features of NM Coupling

1. Shock Absorption

The NM coupling absorbs shocks and vibrations, protecting the canning machinery from damage.

2. Misalignment Compensation

It can compensate for misalignment between shafts, ensuring smooth and efficient operation.

3. Corrosion Resistance

With a corrosion-resistant design, the NM coupling is ideal for use in canning machinery exposed to harsh environments.

4. Maintenance-Free

Once installed, the NM coupling requires minimal maintenance, reducing downtime and maintenance costs.

5. High Torque Transmission

It can efficiently transmit high levels of torque, making it suitable for heavy-duty applications in canning machinery.

Application of NM Coupling in Canning Machinery

1. Precision Alignment

The NM coupling ensures precise alignment between shafts in canning machinery, improving overall performance.

2. Enhanced Efficiency

By reducing energy loss and enhancing power transmission, the NM coupling improves the efficiency of canning machinery.

3. Reliable Performance

With its durable construction and reliable operation, the NM coupling ensures consistent performance in canning machinery.

4. Reduced Downtime

Minimizing the risk of breakdowns and maintenance issues, the NM coupling helps reduce downtime in canning machinery.

5. Cost Savings

By extending the lifespan of canning machinery and reducing maintenance costs, the NM coupling offers long-term cost savings.

Advantages of NM Coupling

1. High Durability

The NM coupling is built to last, providing long-term reliability and performance.

2. Versatile Design

Its versatile design allows for use in various canning machinery applications, ensuring flexibility and adaptability.

3. Optimal Power Transmission

With its high torque transmission capabilities, the NM coupling ensures efficient power transfer in canning machinery.

4. Easy Maintenance

The NM coupling requires minimal maintenance, saving time and costs for canning machinery operators.

5. Customization Options

Customization options are available for the NM coupling, allowing for tailored solutions to meet specific canning machinery requirements.

How to Choose the Right NM Coupling for Canning Machinery

1. Consider Shaft Size

Choose an NM coupling that matches the shaft size of your canning machinery for optimal performance.

2. Evaluate Torque Requirements

Determine the torque requirements of your canning machinery to select an NM coupling with the appropriate torque capacity.

3. Assess Environmental Conditions

Consider the operating environment of your canning machinery to choose an NM coupling with the right corrosion resistance and durability.

4. Check Misalignment Tolerance

Ensure that the NM coupling can compensate for misalignments in your canning machinery to prevent premature wear and damage.

5. Consult with Experts

If you’re unsure about which NM coupling to choose, consult with coupling experts to get personalized recommendations for your canning machinery.

Installation Tips of NM Coupling

1. Follow Manufacturer Guidelines

Refer to the manufacturer’s guidelines for proper installation of the NM coupling to ensure correct alignment and operation.

2. Use Proper Tools

Use the recommended tools and equipment for installing the NM coupling on your canning machinery to prevent damage.

3. Perform Regular Inspections

Regularly inspect the NM coupling for signs of wear or damage and replace it promptly to avoid operational issues.

4. Monitor Performance

Monitor the performance of the NM coupling in your canning machinery to identify any potential issues early on and address them proactively.

5. Replace When Necessary

Replace the NM coupling when it reaches the end of its lifespan or shows signs of wear to maintain optimal performance and safety.

About HZPT

Founded in 2006, HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production for the past 16 years. Our commitment to quality and customer satisfaction has earned us a strong reputation among our European and American customers. We offer a wide range of coupling products, including radial elastic couplings, drum gear couplings, and more. With CE and TUV certifications, we guarantee the highest product quality and competitive prices. Contact us today to learn more about our products and how we can meet your canning machinery coupling needs.