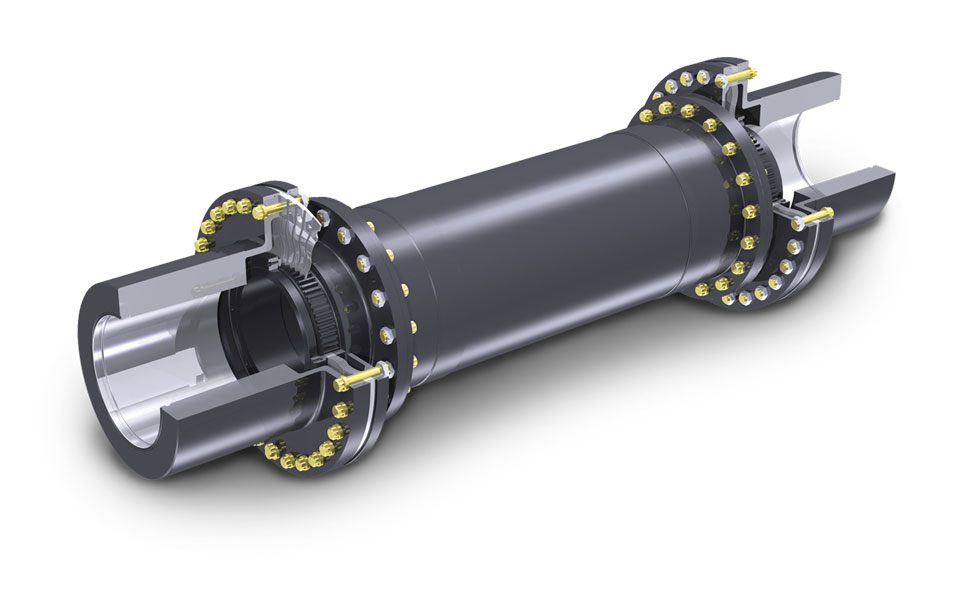

Introduction to NM Coupling for Drilling Rigs

1. High-Quality Material

The NM coupling for drilling rigs is made of durable and reliable materials, ensuring long-lasting performance even in tough drilling conditions.

2. Precision Engineering

Each NM coupling is precision-engineered to provide maximum efficiency and reliability in drilling operations, making it a trusted choice for drilling rigs.

3. Flexibility and Alignment

The NM coupling offers flexibility and easy alignment, allowing for smooth operation and reduced wear and tear on drilling rig components.

4. Shock Absorption

With excellent shock absorption capabilities, the NM coupling helps protect the drilling rig from sudden impacts and vibrations, prolonging its lifespan.

5. Easy Maintenance

The NM coupling is designed for easy maintenance, allowing for quick and hassle-free replacement when needed, minimizing downtime during drilling operations.

6. Cost-Effective Solution

Choosing NM coupling for drilling rigs is a cost-effective solution that provides high performance and durability at a competitive price point, making it a smart investment for your drilling rig needs.

Features of NM Coupling

1. High-Quality Construction

The NM coupling is constructed with high-quality materials for reliable and durable performance.

2. Precision Engineering

Each NM coupling is precision-engineered for maximum efficiency and reliability in drilling rig applications.

3. Flexibility and Alignment

The NM coupling offers flexibility and easy alignment for smooth operation and reduced wear on drilling rig components.

4. Shock Absorption

Excellent shock absorption capabilities protect the drilling rig from impacts and vibrations, extending its lifespan.

5. Easy Maintenance

Designed for easy maintenance, the NM coupling allows for quick replacement, minimizing downtime during drilling operations.

Application of NM Coupling for Drilling Rigs

1. Oil and Gas Industry

The NM coupling is ideal for drilling rigs in the oil and gas industry due to its high-quality construction and shock absorption capabilities.

2. Mining Operations

In mining operations, the NM coupling’s flexibility and alignment features ensure smooth operation and minimal downtime.

3. Construction Projects

For construction projects requiring drilling rigs, the NM coupling’s precision engineering and easy maintenance make it a reliable choice.

4. Geothermal Exploration

Geothermal exploration projects benefit from the NM coupling’s cost-effective solution and durability in challenging drilling conditions.

5. Water Well Drilling

When drilling water wells, the NM coupling’s shock absorption capabilities protect the rig and ensure efficient operation.

Advantages of NM Coupling

1. High-Quality Construction

The NM coupling is made of durable materials for long-lasting performance.

2. Precision Engineering

Precision-engineered for maximum efficiency and reliability in drilling rig applications.

3. Easy Maintenance

Designed for easy maintenance, allowing for quick replacement and minimal downtime.

4. Cost-Effective Solution

A cost-effective choice that provides high performance at a competitive price point.

5. Shock Absorption

Excellent shock absorption capabilities protect the drilling rig and extend its lifespan.

How to Choose the Right NM Coupling

1. Consider the Size and Power Requirements

Choose an NM coupling that matches the size and power requirements of your drilling rig.

2. Evaluate the Operating Conditions

Consider the operating conditions of your drilling rig to select an NM coupling that can withstand the environment.

3. Check for Compatibility

Ensure that the NM coupling is compatible with other components of your drilling rig for seamless integration.

4. Consult with Experts

Seek advice from coupling experts to determine the best NM coupling for your specific drilling rig needs.

5. Quality Assurance

Choose an NM coupling with quality assurance certifications to guarantee performance and reliability.

Installation Tips of NM Coupling

1. Follow Manufacturer Instructions

Always follow the manufacturer’s installation instructions for proper installation of the NM coupling.

2. Ensure Proper Alignment

Align the NM coupling correctly with other components of the drilling rig to prevent misalignment issues.

3. Regular Maintenance Checks

Perform regular maintenance checks on the NM coupling to ensure smooth operation and early detection of any issues.

4. Importance of Replacement

Replace the NM coupling when necessary to maintain optimal performance and prevent costly downtime.

5. Professional Assistance

If in doubt, seek professional assistance for the installation and replacement of the NM coupling to ensure safety and efficiency.

About HZPT

HZPT, established in 2006, is a trusted manufacturer and exporter specializing in coupling design, development, and production. With 16 years of experience, we offer high-quality products, competitive prices, and excellent customer service. Our company is known for its reliability and product quality, with CE and TUV certifications for all our products. We look forward to serving customers in Europe and the United States, providing customized solutions and building successful business relationships worldwide.