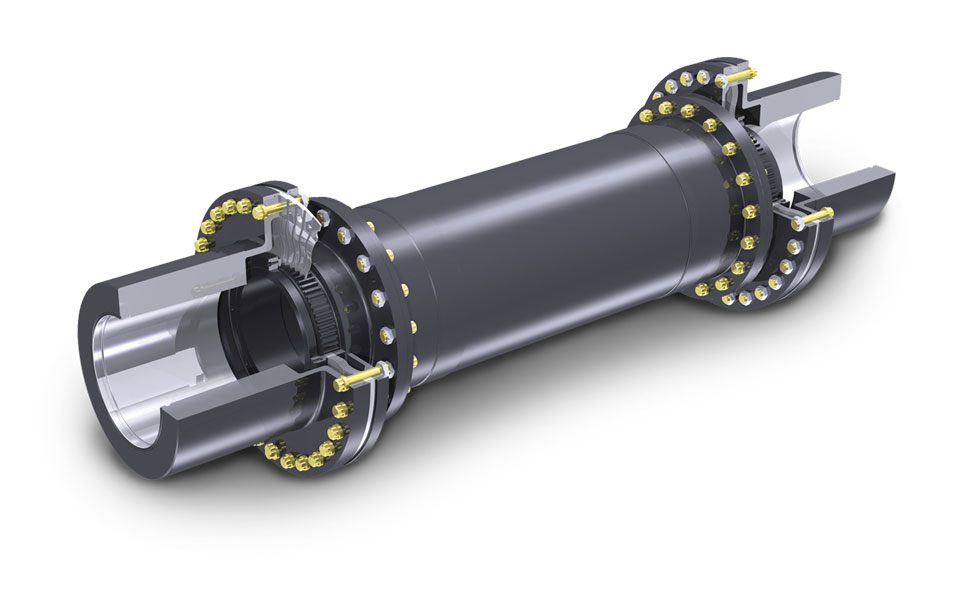

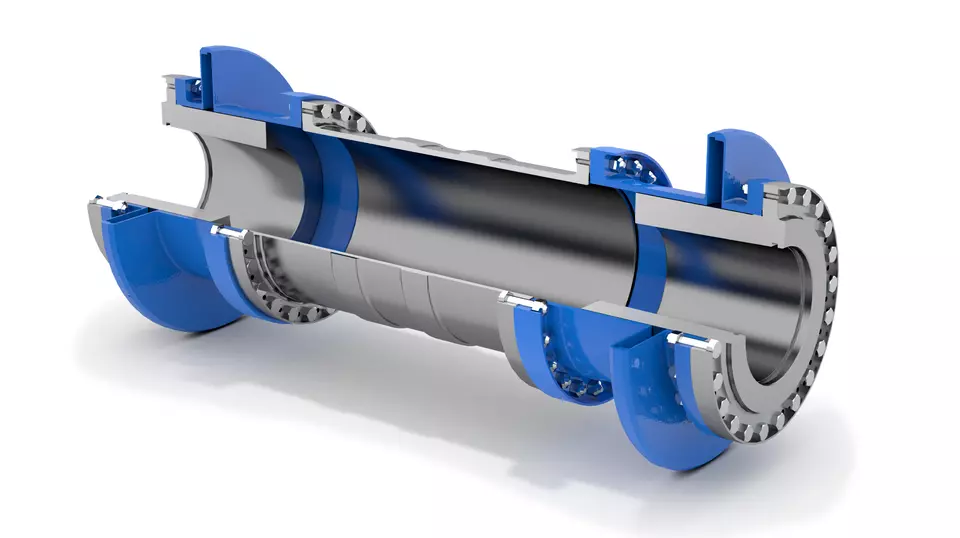

Introducing NM Coupling for Precision Machining Centers

Six Key Points:

- Precision Machining: NM Coupling is designed for precision machining centers, ensuring accurate and efficient operation.

- Durability: Made from high-quality materials, NM Coupling is durable and long-lasting, suitable for heavy-duty applications.

- Flexibility: NM Coupling provides flexibility in alignment and torque transmission, adapting to varying operational needs.

- Low Maintenance: With minimal maintenance requirements, NM Coupling reduces downtime and increases productivity.

- High Torque Capacity: NM Coupling can handle high torque loads, making it ideal for demanding machining processes.

- Precision Performance: NM Coupling ensures precise and consistent performance, essential for precision machining centers.

Five Features of NM Coupling:

- High Misalignment Tolerance: NM Coupling can accommodate angular, parallel, and axial misalignments, ensuring smooth operation.

- Corrosion Resistance: The materials used in NM Coupling provide excellent corrosion resistance, ideal for harsh machining environments.

- Compact Design: With a compact and lightweight design, NM Coupling minimizes space requirements and simplifies installation.

- Shock Absorption: NM Coupling absorbs shocks and vibrations, protecting machinery and enhancing overall performance.

- Easy Installation: NM Coupling is easy to install and maintain, reducing downtime and increasing operational efficiency.

Application of NM Coupling in Precision Machining Centers:

NM Coupling is specifically designed for precision machining centers due to its:

- Ability to handle high torque loads with precision.

- Flexibility in alignment and torque transmission.

- Compact design and easy installation.

- Low maintenance requirements for continuous operation.

- Durability and corrosion resistance for long-term performance.

Advantages of NM Coupling:

- High Quality: NM Coupling is manufactured to high-quality standards, ensuring reliable performance.

- Cost-Effective: With competitive prices, NM Coupling offers excellent value for precision machining centers.

- Customizable: NM Coupling can be customized to meet specific requirements, providing tailored solutions.

- Certified: NM Coupling has CE and TUV certificates, guaranteeing compliance with industry standards.

- Excellent Customer Service: HZPT offers exceptional customer service, supporting customers throughout the product lifecycle.

Choosing the Right NM Coupling:

When selecting an NM Coupling for precision machining centers, consider the following:

- Required torque capacity and speed ratings.

- Alignment flexibility and misalignment tolerance.

- Environmental factors such as temperature and humidity.

- Installation requirements and space limitations.

- Compatibility with existing machinery and components.

Installation Tips of NM Coupling

Five Installation Tips:

- Proper Alignment: Ensure precise alignment of shafts before installing NM Coupling to prevent premature wear.

- Tighten Securely: Follow manufacturer’s instructions for tightening bolts to the recommended torque levels.

- Inspect Regularly: Periodically inspect NM Coupling for signs of wear or damage and replace if necessary.

- Lubrication: Use recommended lubricants to ensure smooth operation and extend the lifespan of NM Coupling.

- Replace When Needed: Replace NM Coupling when reaching the end of its service life to prevent unexpected failures.

About HZPT

HZPT is a leading manufacturer and exporter specializing in coupling design, development, and production since 2006. With a dedicated design and R&D team for 16 years, we offer customizable solutions for global customers. Our comprehensive quality inspection system ensures product reliability, with all products having CE and TUV certificates. HZPT prioritizes customer satisfaction and offers competitive prices and superior service. Choose HZPT for high-quality couplings and reliable performance in precision machining centers.